Construction equipment such as excavators, bulldozers, and cranes operate under heavy loads and extremely high pressures. In these demanding conditions, axial piston pumps are the preferred hydraulic power source. Unlike simple gear or vane pumps, piston pumps can withstand very high pressures (often above 300 bar or 4,350 psi) and deliver large flow rates without excessive wear. For example, modern excavators typically use a high-pressure swash-plate piston pump (often dual-pump designs with a piston main pump and a smaller gear pilot pump) rated around 34 MPa (≈4,900 psi) and peaking near 39 MPa. By contrast, conventional gear pumps usually top out around 20–30 MPa (around 3,000–4,350 psi) and are generally limited to low-precision, lower-pressure tasks. In short, construction piston pumps are chosen because they deliver the high pressure and power density needed in heavy-duty machinery, whereas gear and vane pumps cannot meet those pressure requirements.

Closed-Loop Hydraulic Systems and Oil Purity

Piston pumps achieve their performance through very tight machining tolerances. An axial piston pump’s pistons, shoes, and valve plate clearances are on the order of micrometers. This precision gives excellent volumetric efficiency but also makes the pump sensitive to contamination. Even minor dirt or water in the oil can score the pistons and valve plate. For this reason, modern heavy equipment typically uses closed-loop hydraulic circuits and very good filtration. In a closed-loop (hydrostatic) system, most of the oil circulates between the piston pump and hydraulic motor or actuators in a sealed loop, with only a small charge pump drawing oil from the reservoir. Because the fluid is continuously recirculated and filtered, the hydraulic oil is largely isolated from the outside environment. This design minimizes the ingress of contaminants and maintains the fluid cleanliness that piston pumps require. For example, closed-loop pumps (almost always piston-type variable pumps) need only a small external reservoir since most fluid stays in the loop. In practice, construction piston pumps are protected by advanced filters and by the closed-loop arrangement so that the oil stays clean even under harsh operating conditions

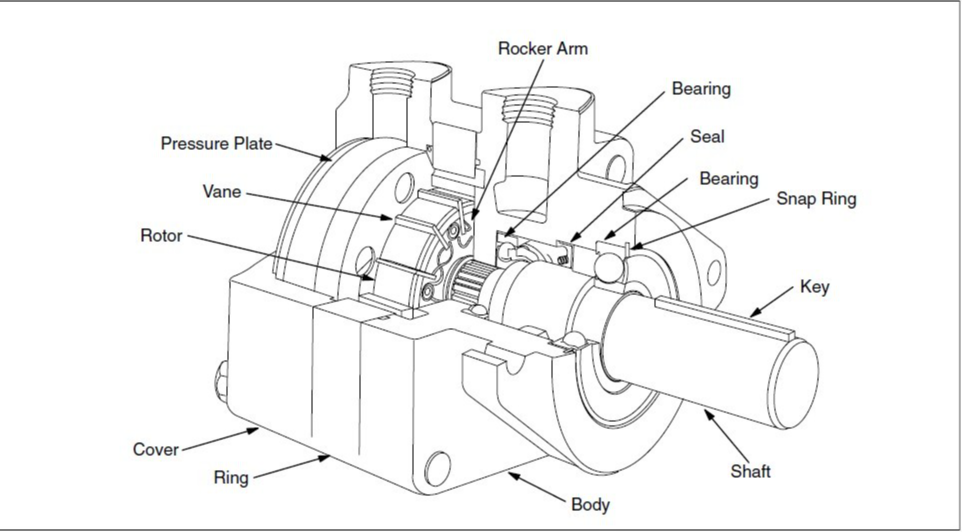

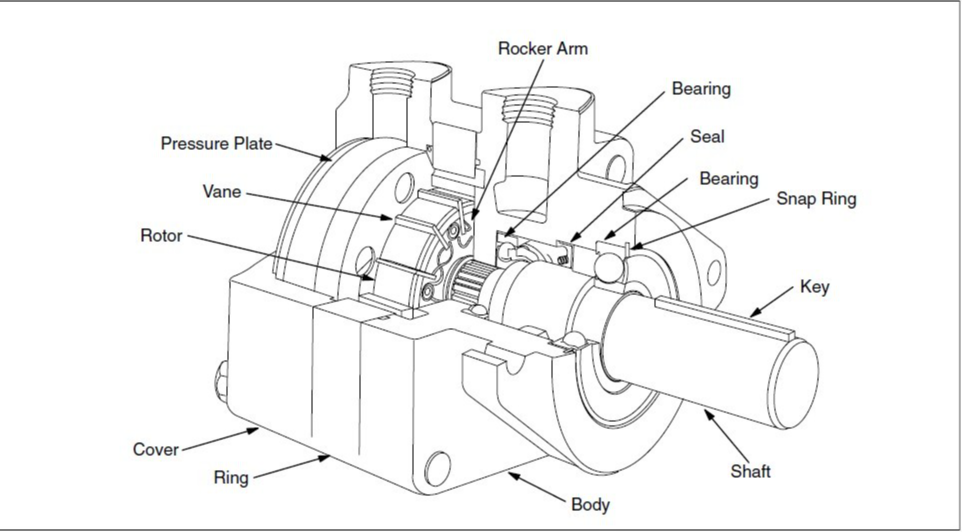

Figure:Cutaway of an axial piston pump slipper and swashplate. Such finely machined sliding interfaces require very clean oil to avoid damage

Variable-Displacement Pumps for Energy Efficiency

Most piston pumps used in construction equipment are variable-displacement swash-plate pumps. In these units, the angle of the swashplate (or bent axis) automatically changes to adjust the piston stroke. The result is that the pump output flow and pressure are modulated to match the real-time load demand. When the machine is idling or under light load, the pump reduces its displacement; when high power is needed (digging or lifting), the displacement increases. This adaptive behavior dramatically reduces energy waste. As one summary of hydraulic pump technology notes, variable-displacement piston pumps “reduce output when demand is low, significantly cut power consumption, [and] improve energy efficiency” by avoiding the relief-valve bypass losses common to fixed pumps. In short, by supplying only the required flow at any given moment, these pumps minimize excess flow, generate less heat, and save fuel. Controlled output also lightens thermal and mechanical stress on the system, extending component life and lowering operating costs

Precise Flow Control for Multi-Function Equipment

Modern construction vehicles often perform several hydraulic functions at once (for example, slewing, travel, lifting, and auxiliary equipment). A single piston pump can feed multiple actuators through a system of priority and load-sensing valves. Because axial piston pumps produce discrete pulses of flow (each piston stroke), they inherently meter oil very smoothly and accurately. In fact, closed-loop variable pumps can reverse flow direction seamlessly without a separate directional valve. This means an operator can move two or more hydraulic functions simultaneously (such as swing and boom) without one “starving” the other. Designers also use load-sensing valves or flow-sharing circuits so that if several actuators demand flow, each gets a proportional share up to the pump’s maximum. The precise flow metering and high stiffness of piston pumps give accurate control: piston pumps maintain steady pressure under changing loads, enabling fine control of cylinder speed and force. In practice, this translates to smooth, predictable operation of multi-function equipment.

For instance, on an excavator the main variable piston pump will directly feed the travel motors, swing motor, and boom/arm cylinders. The pump automatically adjusts to the highest pressure demand among the circuits, while priority valves ensure the swing and travel motors (critical for stability) get flow. Meanwhile a small, separate gear pump typically provides low-pressure pilot oil for the control valves. In these systems, piston pumps supply precise pressure and flow to each actuator and help balance simultaneous demands – a feature not easily achieved with fixed gear pumps alone.

Long-Term Reliability and Cost Efficiency of Piston Pumps

Piston pumps do have higher upfront costs and complexity. Compared to gear and vane pumps, they require more precision machining and robust materials, and their many moving parts mean they can be more expensive to build. However, in heavy-duty service their durability and efficiency pay off over the long term. Renowned pump manufacturers note that piston pumps “offer efficiency and long life under continuous-duty, high pressure loads”. In other words, a quality piston pump can run for tens of thousands of hours with proper maintenance. Because variable pistons adjust flow to the load, they often experience less unnecessary stress than fixed pumps that constantly bypass fluid. This controlled operation “reduces wear and tear on hydraulic components” and leads to longer service intervals.

Hydraulic pump experts advise considering total life-cycle cost: while a gear pump might cost less initially, a premium piston (plunger) pump can be more economical over the life of the machine if reliability is critical. In practice, heavy-equipment fleets accept the higher first cost of piston pumps because they minimize downtime and rebuild cycles. The result is that a piston pump, although costly at purchase, often incurs lower maintenance and replacement costs over the equipment’s life. For procurement professionals and maintenance planners, the calculation usually shows that the piston pump’s longevity and sustained efficiency outweigh its price difference.

Conclusion

In summary, piston pumps are the pump of choice for excavators and construction machinery due to their unmatched high-pressure capability, efficiency, and control. Their design handles the extreme loads and pressures encountered in heavy equipment, whereas gear or vane pumps simply cannot reach the same pressure ratings without sacrificing reliability. Modern systems mitigate the piston pump’s need for clean oil by using closed-loop circuits and robust filtration. Variable-displacement piston pumps further optimize performance by adjusting output to the load, cutting waste and heat. Finally, despite a higher initial investment, the long service life and reliability of piston pumps result in lower lifecycle costs and better uptime. Hydraulic pump comparisons consistently show that for demanding construction applications, the “construction piston pump” is the most effective solution

FAQ

1. Why do excavators and construction machinery use piston pumps instead of gear or vane pumps?

Construction machinery operates in high-load and high-pressure environments. Piston pumps can withstand extremely high pressures, typically above 30–35 MPa, while gear and vane pumps are limited to much lower pressure ranges. Therefore, piston pumps are selected because they deliver higher power density, stronger output torque and better stability in demanding engineering applications.

2. Are piston pumps too sensitive to contamination for use in construction equipment?

Although piston pumps require cleaner hydraulic oil due to their precision-machined internal components, modern construction machinery uses closed hydraulic circuits and multi-stage filtration systems. These designs prevent dust, moisture and solid particles from entering the system, allowing piston pumps to work reliably even in harsh outdoor environments.

3. How do variable-displacement piston pumps improve energy efficiency?

Variable piston pumps automatically adjust displacement based on real-time load conditions. When load is light, the pump reduces output, and when load increases, displacement rises accordingly. This reduces hydraulic losses, minimizes heat generation, lowers fuel consumption and prevents unnecessary energy waste during machine operation.

4. Can one piston pump supply several actuators at the same time?

Yes. High-precision flow delivery and stable pressure output allow a single piston pump to supply multiple hydraulic actuators simultaneously. Combined with load-sensing valves and priority control systems, piston pumps can distribute flow proportionally without starving any actuator, ensuring stable multi-function control.

5. Are piston pumps more expensive to maintain than other hydraulic pumps?

Piston pumps have a higher initial purchase cost, but they typically offer longer service life, lower internal leakage, better volumetric efficiency and higher reliability under continuous high-pressure loads. These advantages reduce downtime, overhaul frequency and long-term operating cost, making piston pumps more economical over the lifecycle of construction machinery.

6. Why are piston pumps considered more suitable for excavators?

Excavators frequently undergo compound motions such as travel, swing, digging, lifting and fine-positioning. These actions require fast response, high pressure and precise flow control. Piston pumps meet these requirements through closed-loop structure, displacement control, high stiffness and stable output, making them the most suitable hydraulic pump design for excavator systems.

7. What hydraulic pump comparison factors favor piston pumps for engineering applications?

Key comparison criteria include maximum system pressure, efficiency, internal leakage, control accuracy and adaptability under load changes. Piston pumps outperform gear and vane pumps in all these categories, making them the preferred hydraulic power source in construction equipment.

8. How does closed-loop design protect piston pumps in construction equipment?

Closed-loop hydraulic circuits keep hydraulic oil within a sealed flow path between pump and actuators. The oil rarely contacts the external environment, and filtration continuously removes contaminants. This preserves oil purity, protects precision components and ensures long-term stability of piston pumps.