-

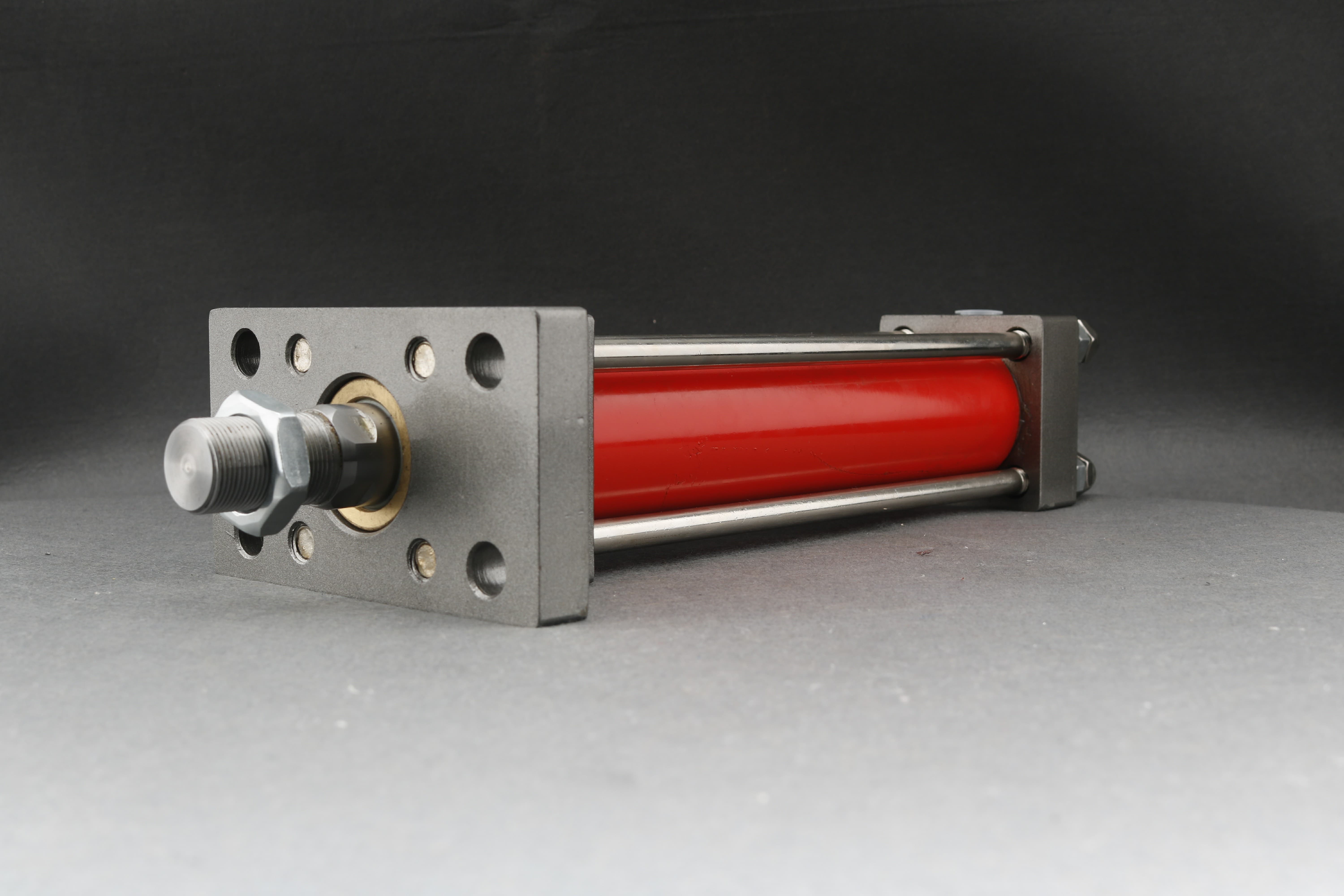

The important of high-quality hydraulic products lies in the careful selection and strict inspection of raw materials. We only purchase materials from trusted suppliers who meet our strict quality standards. Once the materials arrive, they will be fully inspected, including chemical composition analysis and mechanical property testing, to ensure that only materials that meet durability and performance requirements enter the production line.

-

Precision processing and manufacturing are essential in the manufacturing process of hydraulic products. Our production lines are equipped with CNC machines and automation systems to ensure consistent and accurate processing of components such as hydapumps, valves and motors. During the processing process, real-time monitoring systems check dimensional accuracy, surface finish and tolerance levels. Any deviations from specifications are immediately addressed to prevent defects from continuing to spread in the production process.

-

The assembly of hydraulic components is a critical stage that must be highly precise. Our assembly lines strictly follow standard operating procedures (SOPs) to ensure that each component is carefully assembled. During the assembly process, each unit undergoes multiple inspections, including torque testing of fasteners, alignment verification of shafts, and pressure testing of seals. These inspections are designed to detect potential problems early and ensure that each assembled product is strong, reliable, and leak-free.

-

Process testing is an important part of our quality control strategy. Hydraulic components undergo multiple rounds of functional testing at each stage on the production line. These tests include pressure testing, flow measurement, and temperature resistance checks. By performing these tests during the production process, we are able to identify and correct any functional differences before the final product stage, ensuring that each unit will meet performance expectations.

-

Before any hydraulic product leaves the factory, it undergoes a comprehensive final inspection. This includes a full range of performance tests that simulate actual working conditions. Products will undergo maximum pressure testing, fatigue testing, and durability testing to confirm their reliability and durability. In addition, we perform a visual inspection to ensure that there are no surface defects or flaws. Only products that pass all rigorous tests are approved for packaging and shipment.

-

We keep detailed records of every step in the production and testing process to ensure that every hydraulic product is fully traceable. Each unit is assigned a unique serial number, allowing us to trace it back to the specific raw material batch, processing settings, and assembly procedures. This traceability is essential for quality control and provides a clear audit record in the event of any problems after delivery. In addition, with continuous feedback from these records, we can continuously optimize processes and improve product quality.

-

Quality control is not a static process, but a cycle of continuous improvement. We actively collect customer feedback and conduct regular internal audits to identify areas for improvement. By integrating customer feedback into our quality control process, we ensure that hydraulic products not only meet current standards, but are also able to adapt to future industry challenges.

Mining Machinery (Shearer)" />

Mining Machinery (Shearer)" />  Metallurgical Machinery" />

Metallurgical Machinery" />  Drilling Machinery" />

Drilling Machinery" />  Construction Machinery" />

Construction Machinery" />  Ship Equipment" />

Ship Equipment" />  Agricultural Machinery" />

Agricultural Machinery" />