When engineers and technicians ask what is direction control valve, they are usually looking for a clear understanding of how fluid flow is managed inside a hydraulic system. A direction control valve is one of the most critical components in any hydraulic or pneumatic circuit. It directs the flow of hydraulic fluid, enabling actuators such as cylinders or motors to move forward, backward, or hold a specific position.

Without direction control valves, hydraulic systems would lack precision, safety, and efficiency. Let’s dive deeper into their definition, working principle, and different types.

What is a Direction Control Valve?

A direction control valve is a device that controls the start, stop, and change of direction of fluid flow in a hydraulic circuit. It enables actuators to perform linear or rotary motion in both directions.

The usefulness of a DCV lies in its ability to shift from one position to another, which allows hydraulic actuators to achieve complex and precise operations.

Direction control valves can be actuated in different ways:

Main Functions

Start, stop, accelerate, and decelerate hydraulic actuators

Change the direction of hydraulic motor or cylinder motion

Isolate a branch of a hydraulic circuit

Allow pressure relief and return flow to the tank

Enable free flow from pump to reservoir when required

How Does a Direction Control Valve Work?

Broadly, a direction control valve works by shifting a spool, poppet, or other closure element to open or block passages for fluid. Once hydraulic oil triggers the valve, it moves instantly to a new position, changing flow paths and actuator direction.

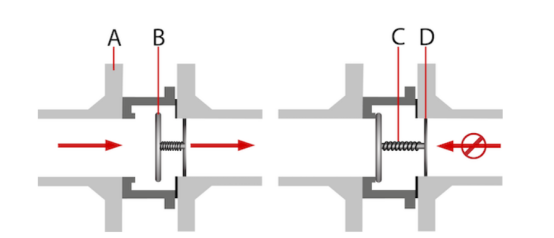

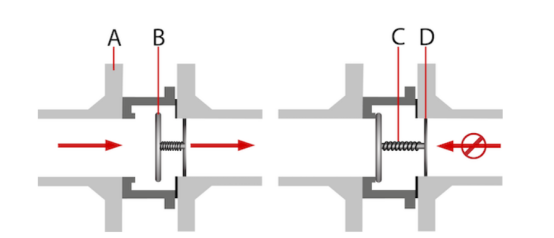

For example, a Check Valve is a simple 2-way direction control valve that allows fluid to flow in one direction while preventing reverse flow.

Example: Spring-Loaded Check Valve

Fluid enters the inlet and pushes against the poppet or valve disc.

When pressure is high enough, the spring compresses, opening the passage.

Once pressure drops, the spring pushes the poppet back, closing the valve and preventing backflow.

Types of Direction Control Valves

1. Check Valve

A Check Valve (one-way valve) permits fluid flow in only one direction. It is widely used in circuits where backflow would cause damage or instability.

2. Spool Valve

A Spool Valve uses a sliding spool inside a cylinder housing to control flow paths. Depending on the spool position, the valve can connect, block, or redirect fluid passages. It is versatile and widely used in mobile machinery.

3. Poppet Valve

A Poppet Valve uses a poppet element that seals against a seat. These valves provide tight sealing and are ideal for high-pressure applications requiring zero leakage.

4. Solenoid Valve / Solenoid-Operated Valve

A Solenoid Valve uses an electromagnetic coil to shift the valve position automatically. A Solenoid-Operated Valve is popular in automation because it allows remote, fast, and reliable operation.

5. Pilot-Operated Valve

A Pilot-Operated valve uses system pressure or a smaller pilot signal to shift the main valve. This design allows handling of very high flow rates and pressures without requiring large actuators or electrical coils.

Why Trust Blince? — Proven Expertise in Directional Control Valves

At Blince, our reputation is built not on theory, but on years of real-world engineering experience and innovation in hydraulic control systems.

One of our most remarkable projects involved providing a direction control valve solution for an international construction machinery manufacturer. Their system faced repeated failures under continuous heavy-duty cycles, particularly when exposed to high flow and high-pressure fluctuations. Standard Solenoid Valves from the market could not withstand the environment, leading to downtime and expensive maintenance.

Blince engineers developed a new generation of Pilot-Operated valves, integrating precision machining, advanced sealing, and optimized spool design. The result was a directional control valve system that passed extreme endurance tests and achieved zero field failures.

Today, Blince is trusted worldwide for its expertise in direction control valves, solenoid valves, spool valves, poppet valves, check valves, and pilot-operated valves. We don’t just supply products—we provide solutions that turn engineering challenges into competitive advantages.

How to Select the Right Direction Control Valve

When choosing the right direction control valve, consider the following factors:

Flow rate and system pressure requirements

Type of actuator (cylinder or motor)

Control method (manual, solenoid-operated, or pilot-operated)

Need for Check Valve, Spool Valve, or Poppet Valve depending on sealing requirements

Environmental conditions (temperature, contamination, exposure to chemicals)

Selecting the correct valve not only ensures safety but also extends equipment life and reduces total cost of ownership.

Conclusion

So, what is direction control valve? In short, it is the “traffic director” of a hydraulic system—responsible for starting, stopping, and changing the flow of hydraulic fluid to enable precise motion control.

From Check Valves to Spool Valves, Poppet Valves, Solenoid Valves, and Pilot-Operated valves, each type has unique strengths that fit specific industrial needs.

At Blince, we leverage deep technical expertise and innovation to deliver reliable, high-performance solutions that keep industries moving forward.

Blince has helped global machinery manufacturers reduce downtime and boost performance. Reach out now for a customized quote on direction control valves, solenoid valves, pilot-operated valves, spool valves, poppet valves, and check valves.

Blince Hydraulic

Blince is a global leader in hydraulic equipment manufacturing, specializing in hydraulic motors, orbital motors, hydraulic valves, hydraulic pumps, hydraulic systems, hydraulic cylinders, and hydraulic hoses. With over 20 years of industry experience and trusted by more than 5,000 customers worldwide, we are committed to delivering high-performance hydraulic solutions for agriculture, construction, forestry, and industrial applications.

We are equipped with state-of-the-art production facilities, strong R&D capabilities, and advanced technology, all of which are supported by sophisticated testing equipment. Our commitment to quality is reflected in our compliance with ISO 9001 and CE standards, and we are proud to own 10 registered patents.

Blince products are exported to more than 100 countries, serving global machinery manufacturers with 24/7 technical support and rapid delivery. Choosing Blince means choosing efficiency, durability, and innovation in every hydraulic solution.

Learn more at: www.blince.com