In the world of hydraulic drive systems, the low speed hydraulic motor plays a vital role in delivering consistent torque and stable performance. When equipment requires less than 50 revolutions per minute (rpm), users often turn to low speed orbital motors or high torque hydraulic motors to achieve reliable motion. Brands such as Danfoss and White have set industry standards with advanced designs, while radial piston motors and ball motors continue to serve as specialized solutions for extremely low speed demands. Understanding the hydraulic motor classification is crucial for engineers, operators, and buyers who need dependable power in construction, agriculture, forestry, and material handling.

What Is Low Speed Hydraulic Motor?

Hydraulic motors are commonly classified by their operating speed range:

High speed motors: above 500 rpm

Medium speed motors: 300–500 rpm

Low speed motors: below 300 rpm

When the requirement drops below 50 rpm, it becomes a challenge because many hydraulic motors cannot achieve this range without external reduction devices such as gearboxes, sprockets, or belt drives. In such cases, specialized low speed high torque (LSHT) hydraulic motors are the solution.

Types of Low Speed Hydraulic Motors

1. Low Speed Orbital Motors (Cycloidal Motors)

The most common option is the orbital motor, also known as a low speed orbital motor. In China, the OMER series hydraulic orbital motor is a popular choice, while internationally, the Danfoss RE series and White TG series are well-recognized for their stable low-speed performance.

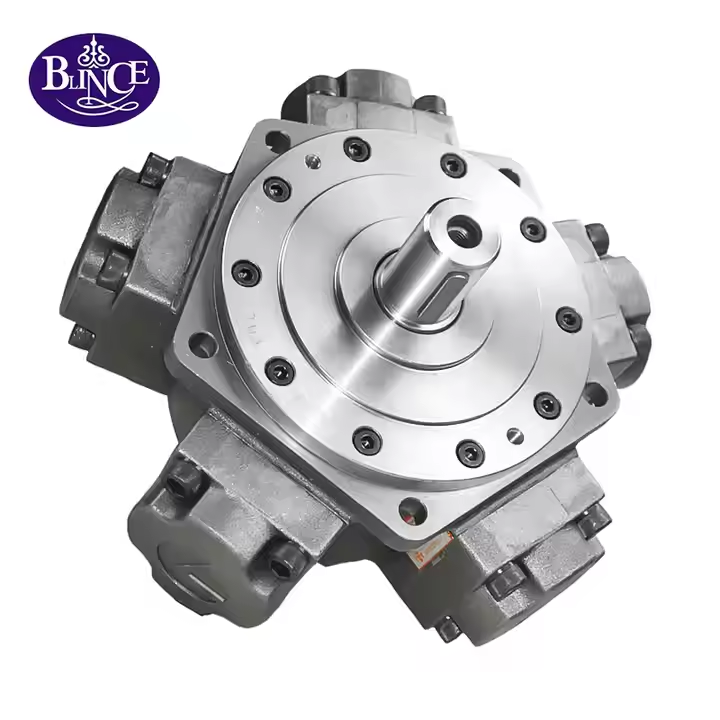

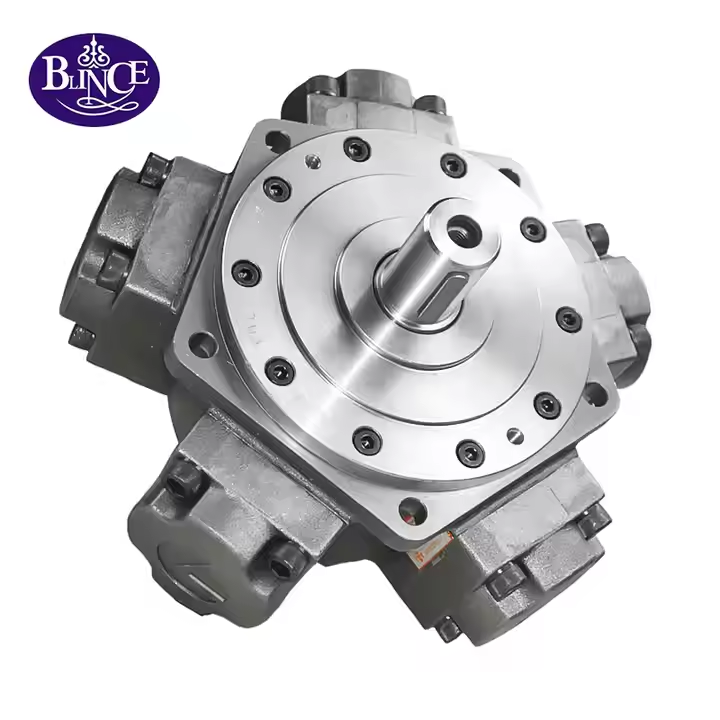

2. Radial Piston Motors

When extremely low speeds are required, radial piston motors are an excellent solution. The more pistons the motor has, the lower the speed it can achieve. For instance:

An 11-piston radial motor can run at about 10 rpm.

With special flow and balance valve groups, it can reach as low as 5 rpm.

The drawback is higher cost, as the valve group customization adds to the price.

3. Ball Motors (Inner Curve Motors)

Also called steel ball motors or inner curve motors, these are large displacement units capable of extremely low speeds.

Why Trust Blince? — Proven Expertise in Low Speed Hydraulic Motors

At Blince, our strength lies not in theory but in decades of real-world engineering and innovation in hydraulic motor classification and system optimization.

One of our most challenging projects came from an agricultural machinery manufacturer who needed a low speed hydraulic motor capable of running steadily at under 20 rpm without using additional gear reducers. Their previous suppliers struggled: standard orbital motors could not maintain smooth motion at such low speed, and repeated failures caused costly downtime and frustrated operators.

Blince engineers responded by analyzing the system requirements in detail. Instead of relying on off-the-shelf designs, we integrated large-displacement orbital motor technology, advanced sealing systems, and precision spool valve control. The result was a customized low speed high torque hydraulic motor that delivered stable performance at 15 rpm with reliable torque output. The customer reported zero failures after extended field use—an achievement that positioned Blince as their long-term strategic partner.

Today, Blince is trusted globally for its expertise in low speed orbital motors, radial piston motors, and ball motors, as well as in hydraulic valves that enhance system efficiency. Whether the requirement is for construction machinery, forestry equipment, road machinery, or agricultural vehicles, we don’t just deliver products—we provide engineered solutions that turn difficult motion control challenges into reliable competitive advantages.

Other Methods to Achieve Low Speed Stability

Apart from motor design, engineers sometimes use hydraulic valves to regulate flow:

Return line throttling: Adding a one-way throttle valve to the return line increases back pressure and reduces speed fluctuation.

⚠️ However, this method can cause excessive back pressure and oil leakage if not properly managed.

Key Considerations for Low Speed Applications

When using a low speed high torque hydraulic motor:

Avoid applying excessive load or torque at very low speeds.

Ensure stable system flow and pressure.

Keep oil temperature under control to maintain long-term motor stability.

In no-load conditions, some hydraulic motors can even run at 1 rpm, but stability under load is the real test of motor design.

FAQs About Low Speed Hydraulic Motors

Q1: What is the difference between a low speed orbital motor and a radial piston motor?

A low speed orbital motor (like Danfoss or White TG) is cost-effective and compact, suitable for most low speed applications. Radial piston motors deliver ultra-low speed (down to 5 rpm) with higher torque, but they are more expensive.

Q2: Can a standard hydraulic motor achieve 10 rpm?

Not usually. Most standard motors need external reduction gearboxes. Only specialized motors such as large displacement orbital motors, radial piston motors, or ball motors can achieve 10 rpm directly.

Q3: Which brand is better for low speed hydraulic motors?

Both Danfoss and White are well-known for stability and reliability. Domestic series like OMER are also widely used due to cost efficiency.

Q4: How can I improve low speed stability?

Use a motor with higher displacement, add flow control valves carefully, and maintain proper oil temperature and pressure balance.

Q5: Are ball motors (QJM series) reliable at low rpm?

Yes, ball motors are designed for large displacement and low speed operation, but precision manufacturing adjustments are required for long-term stability.

Need a customized hydraulic solution or want to know about our high-quality hydraulic components? Contact Blince Hydraulic experts immediately for a free consultation! You can make a call+86-769 8515 6586 or send an email to sales01@blince.com

Blince Hydraulic

Blince is a global leader in hydraulic equipment manufacturing, specializing in hydraulic motors, orbital motors, hydraulic valves, hydraulic pumps, hydraulic systems, hydraulic cylinders, and hydraulic hoses. With over 20 years of industry experience and trusted by more than 5,000 customers worldwide, we are committed to delivering high-performance hydraulic solutions for agriculture, construction, forestry, and industrial applications.

We are equipped with state-of-the-art production facilities, strong R&D capabilities, and advanced technology, all of which are supported by sophisticated testing equipment. Our commitment to quality is reflected in our compliance with ISO 9001 and CE standards, and we are proud to own 10 registered patents.

Blince products are exported to more than 100 countries, serving global machinery manufacturers with 24/7 technical support and rapid delivery. Choosing Blince means choosing efficiency, durability, and innovation in every hydraulic solution.

Learn more at: www.blince.com