Hydraulic system backpressure is an important but often overlooked aspect of industrial machinery performance. For B2B buyers, OEM engineers, and purchasing managers in industries from construction to manufacturing, understanding how backpressure works can help in selecting the right hydraulic components and maintaining efficient systems. In markets like Russia and Latin America , factoring in local conditions – from Russia’s cold climate to Latin America’s heat – is crucial when managing hydraulic backpressure. This article provides a comprehensive guide to hydraulic backpressure, covering what it is, why it matters, how to reduce it, and which industrial hydraulic components (such as valves, cylinders, and cooling systems) can help optimize your system.

What Is Hydraulic Backpressure?

Hydraulic backpressure refers to the pressure that resists fluid flow on the return (outlet) side of a hydraulic circuit In simple terms, it is the pressure present in the return line due to restrictions or load, essentially a reverse pressure against the flow. Backpressure occurs when the fluid’s path back to tank is restricted, causing a pressure buildup backward through the line. This is commonly the pressure between an actuator (like a motor or cylinder) and the reservoir, after the fluid has done its work. For example, if a return filter, valve, or narrow pipe is in the line, the fluid has to push through it, creating resistance and thus backpressure.

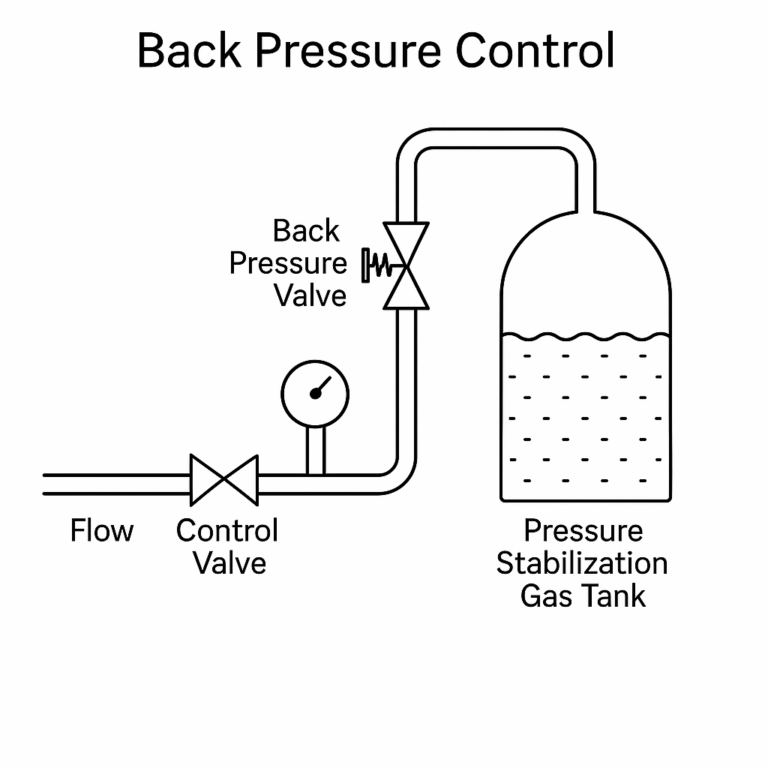

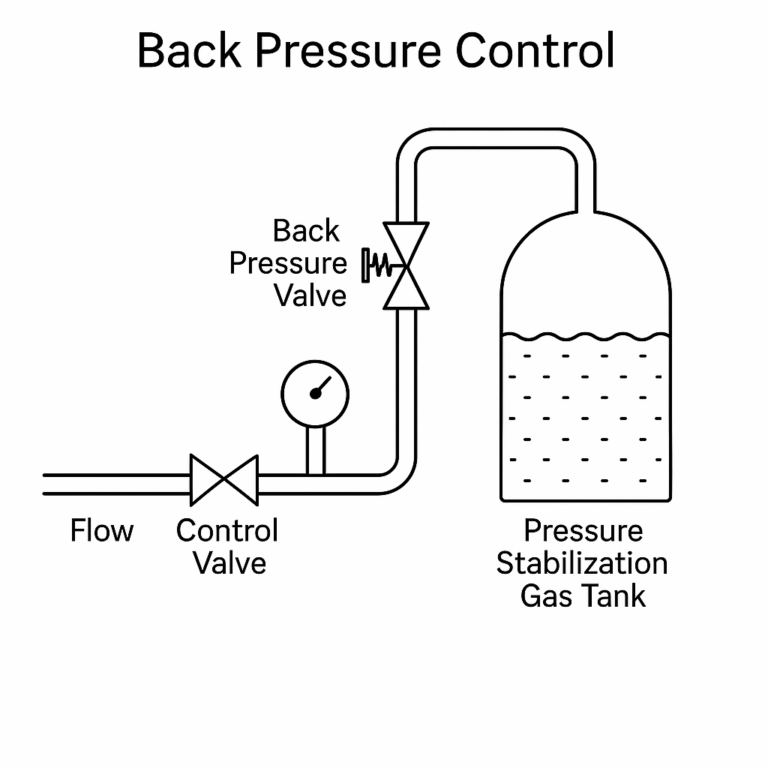

Some backpressure is normal in hydraulic systems and can even be intentionally introduced. A dedicated backpressure circuit uses a valve in the return line to create a small resistance, typically setting the backpressure around 3–8 bar (0.3–0.8 MPa). This slight counter-pressure helps stabilize the system. Hydraulic cylinders often benefit from a bit of backpressure to move more smoothly – it acts like a cushion that prevents the cylinder from dropping too fast or jerking. In fact, adding a backpressure valve in the return line can improve an actuator’s motion stability and reduce “crawling” (stick-slip motion). Hydraulic pressure relief valves are frequently used as backpressure valves in such circuits, set to maintain a low constant pressure in the return line. Many engineers follow a guideline of keeping backpressure to roughly 10–20% of the system’s working pressure – enough to stabilize flow but not so high as to waste energy.

Why does backpressure exist? In any hydraulic system, every component (hoses, fittings, valves, filters, etc.) introduces some resistance to flow. The fluid’s own characteristics also play a role – if the hydraulic oil is thick (high viscosity), it creates more friction and hence higher backpressure when flowing through passages. In essence, backpressure is a byproduct of pushing fluid through a confined system. However, engineers often design for an optimal backpressure: for example, ensuring a minimum return-line pressure can prevent cavitation (when rapid flow and low pressure cause vapor bubbles). Hydraulic flow control valves (throttle valves) intentionally create a pressure drop to regulate actuator speed, which inherently adds some backpressure upstream. The key is managing backpressure so that it benefits stability without causing inefficiency or damage.

What Causes High Backpressure in Hydraulic Systems?

While a small amount of backpressure is useful, excessive backpressure is usually a sign of flow restrictions or system issues. Several factors can cause abnormally high backpressure in a hydraulic return line:

Flow Restrictions and Resistance: Any component that narrows or slows the flow will raise backpressure. Long or undersized hoses, many sharp bends or elbows in plumbing, and small-orifice fittings create friction that opposes the fluid flow. For example, using a hose that is too narrow for the pump’s flow rate, especially over a long distance, means the fluid has to squeeze through, leading to a pressure buildup. Simply moving up to a larger hose diameter can help alleviate this kind of backpressure. Likewise, quick-release couplings often have smaller internal passages; using too many quick couplers or ones that are undersized will restrict flow and spike the return pressure.

Fluid Viscosity and Temperature: The thickness of hydraulic oil has a direct effect on backpressure. Thicker fluids (for instance, when using high-viscosity oil or when oil is cold) create more resistance inside pipes and valves, causing higher backpressure. Conversely, very thin (hot) fluid flows more easily, which can reduce pressure drop. This means climate plays a role: in cold regions like Russia, hydraulic oil may thicken if not warmed up, leading to elevated backpressure until the system reaches operating temperature. In hot climates such as Mexico or Brazil, oil stays thin but high ambient temperatures can cause other issues (like oil degradation) if backpressure continuously generates heat. Selecting the right oil viscosity for your operating temperature and using hydraulic oil heaters or coolers when necessary will help keep backpressure within normal levels

Improper Component Sizing: Using components not properly sized for the flow can introduce unnecessary resistance. If a return line filter or heat exchanger (cooler) is too small for the flow rate, it will cause a significant pressure drop as fluid pushes through it. Similarly, valves with too low a flow capacity will throttle the return. Every component (pipes, fittings, valve ports) must be chosen with the maximum return flow in mind, which can be much higher than pump flow in certain conditions. For example, large differential hydraulic cylinders expelling fluid from the rod end can output a return flow several times the pump supply flow; if the return filter isn’t sized for that peak flow, dangerous backpressures can occur. Thus, engineers must account for worst-case flow rates when selecting return-line components.

Clogged or Dirty Filters: A very common cause of rising backpressure over time is a clogged return filter. As the filter element fills with contaminants, it becomes harder for fluid to pass through, causing a pressure buildup at the filter inlet. Clogging of return filters leads to increased backpressure, which in turn makes actuators sluggish or unresponsive. In fact, a blocked filter can cause such a significant return line pressure rise that many filter assemblies include a bypass valve to prevent damage. If you notice slow cylinder movements or a pressure alarm in the return line, a clogged filter could be the culprit. Regular maintenance and timely replacement of hydraulic oil filters are essential to avoid this issue.

Excessive Backpressure Valve Setting: If your system uses a backpressure valve (such as a partially closed flow control or a relief valve on the return line), setting it too high will obviously create high backpressure. For instance, setting a backpressure valve much above the typical 3–8 bar range might unnecessarily increase the load on the pump and actuators. Sometimes, maintenance personnel may tighten a relief or sequence valve not realizing it’s causing a constant backpressure in the return. Always adjust such valves according to the machinery requirements and the tolerance of components (e.g. many motor case seals can only handle a few bar of backpressure safely).

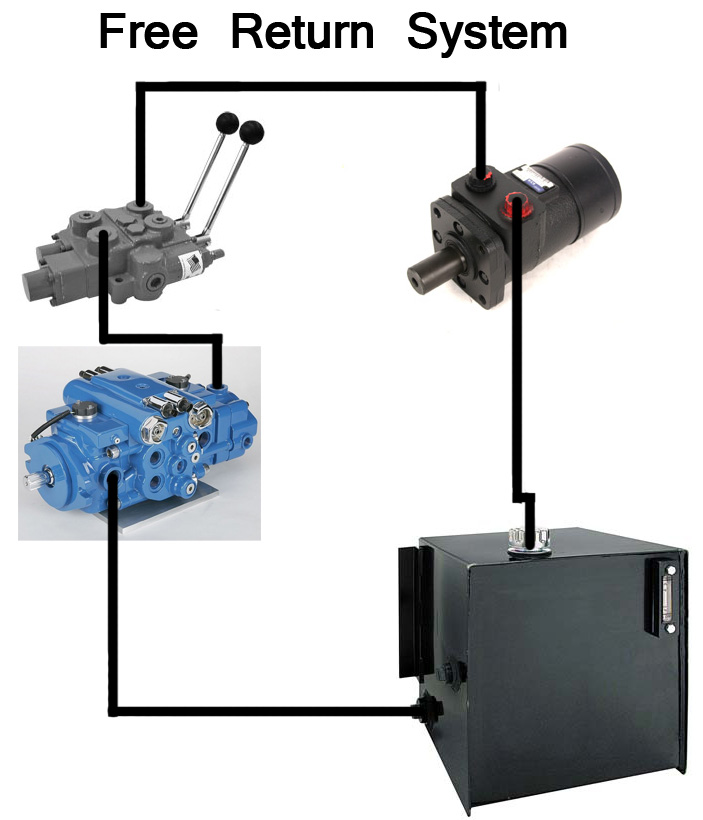

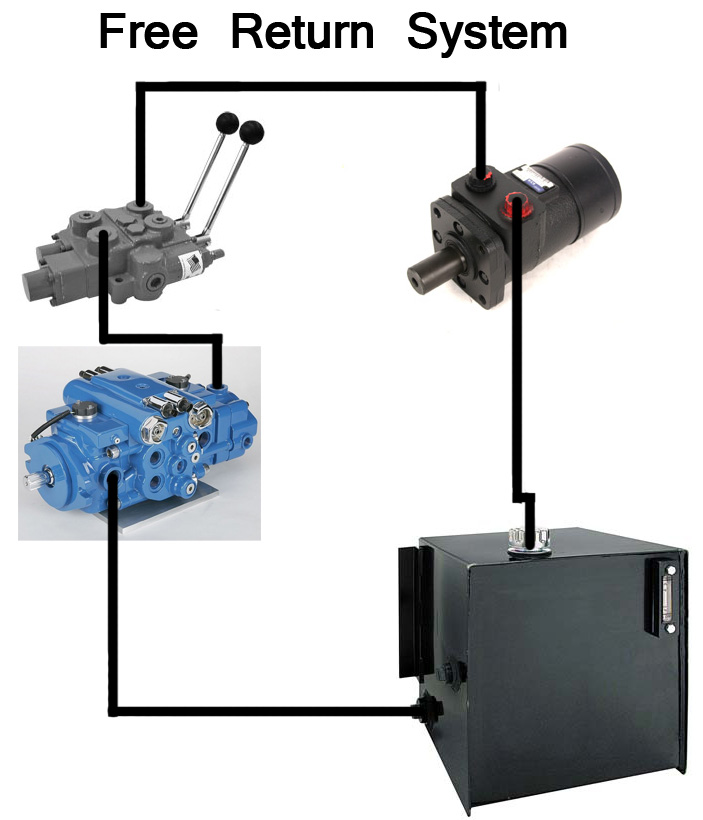

Shared Return Lines and Improper Circuit Design: In hydraulic circuit design, routing multiple functions into a single return line or through a common manifold can cause interactions and added backpressure. For example, if a high-flow component like a hydraulic motor shares the same return path (through a directional control valve) as other functions, the combined flow might overwhelm the return capacity. Hydraulic motors in particular are sensitive – if their case drain or return sees high backpressure, it can blow out seals or reduce performance. That’s why in many cases, hydraulic motors are given a “free flow” return direct to tank. If a motor only turns in one direction and doesn’t need the valve to meter its return, piping its return line straight to the reservoir (bypassing restrictive valve blocks) ensures the flow goes back with virtually no resistance. In summary, poor return line routing or combining too many returns without adequate sizing can elevate backpressure.

By recognizing these causes, hydraulic system designers and maintenance teams can troubleshoot high backpressure by checking for blockages, ensuring components are properly sized, and reviewing the circuit layout.

Why High Backpressure Is a Problem

Excessive backpressure in a hydraulic system is undesirable and can lead to multiple issues affecting performance, efficiency, and component longevity. Here are the key problems caused by high backpressure:

Reduced Efficiency & Wasted Energy: High backpressure means the hydraulic pump has to work harder to push fluid through the system. The pump expends extra energy just to overcome this resistance rather than doing useful work. As a result, the overall system efficiency drops. You might notice slower actuator speeds and a drop in machine performance because some of the pump’s output flow is effectively “robbed” by the opposing pressure. This also translates to higher energy consumption (fuel or electricity), raising operating costs. For companies focused on productivity and sustainability, this inefficiency can be a significant concern – the machine may run slower and consume more power than necessary.

Overheating of Fluid: When energy is wasted as pressure drop in the return line, it is mostly converted into heat. Fluid forced through narrow passages or clogged filters generates friction heat. Therefore, excess backpressure often causes the hydraulic oil temperature to rise. Over time, this can lead to overheating of the hydraulic fluid, degrading its properties and viscosity. Hot oil not only has lower viscosity (which can alter how the system behaves) but also can oxidize or break down faster, reducing the oil’s life. If you observe oil running hotter than normal, backpressure-induced losses could be a contributing factor. In summary, too much backpressure puts thermal stress on the system, which is why robust hydraulic cooling systems (oil coolers) or larger reservoirs might be needed in systems that inherently run with higher return pressures (common in tropical climates or high-duty cycles).

Increased Wear and Component Stress: Hydraulic components are designed with certain pressure limits. When backpressure is high, parts like pumps, motors, and cylinders are under strain even when they are supposed to be “off load.” This constant extra pressure can accelerate wear and tear on components. For example, a pump’s internal seals and rotating group see more stress, potentially shortening pump life. Hydraulic motors, especially those with case drains, can suffer seal failures if the drain line pressure exceeds their rating – excessive backpressure can blow out shaft seals or cause leaks in motors and cylinders. Hoses and fittings might also see higher pressure on them than anticipated, which can weaken them over time. In short, running with high backpressure is like driving a car with the parking brake slightly engaged – everything works harder and wears out faster. Key signs of backpressure-related wear include more frequent seal replacements, hose bulging or leakage, and unusual strain on return-line fittings.

Potential for System Malfunctions or Failure: In extreme cases, uncontrolled backpressure can lead to system malfunctions or even catastrophic failure. If a return line is blocked and pressure builds up beyond safe limits, something will give – possibly a hose bursting or a fitting blowing off, resulting in sudden oil loss. A high backpressure may also interfere with the operation of sensitive components; for instance, some directional control valves or pilot-operated valves might not shift correctly if backpressure on their tank port is above a certain threshold. Additionally, actuators might behave erratically; a cylinder could unexpectedly creep or not retract fully due to pressure trapped in the return side. Safety mechanisms like pressure relief valves should kick in to prevent damage, but if they are absent or set incorrectly, the risk of over-pressurization exists. A notable example is a return filter without a bypass – if it’s completely clogged, the backpressure could spike until a line ruptures. The consequences include machine downtime, environmental hazards from oil spills, and safety risks to personnel. This is why many hydraulic filters include bypass valves and why pressure relief valves are critical as a last line of defense against excessive pressure.

To sum up, high backpressure is detrimental because it wastes energy, creates heat, and strains components, potentially causing premature failures. Keeping backpressure within design limits is essential for reliable and efficient hydraulic system operation.

How to Reduce and Manage Backpressure (Solutions)

Keeping hydraulic backpressure at an optimal level involves both good design practices and proper maintenance. Here are several solutions and best practices to manage or reduce backpressure in your hydraulic system:

Optimize Hydraulic Circuit Design: In the design phase, ensure the return path for fluid is as free-flowing as possible. Use adequately sized return lines and avoid unnecessary bends or tight elbows that add resistance. If multiple actuators share a return line, make sure the combined flow won’t overwhelm the line or create bottlenecks. It’s often wise to provide dedicated return lines for high-flow components like hydraulic motors – for instance, routing a motor’s return oil directly to the tank (bypassing valve manifolds) so that it encounters minimal restriction. Many modern hydraulic valves and manifolds are designed with internal passages optimized for flow; choosing a valve block with a “low backpressure” design (one that advertises tank port pressure of only e.g. 1 MPa or less) will minimize energy losses. Good design also extends to component placement: mounting return filters and coolers in positions that allow smooth flow (and using diffusers on the tank return) can prevent sudden backpressure jumps and fluid aeration.

Select the Right Components (Flow Capacity and Quality): All components in the return line should be rated for higher flow than the maximum pump output (accounting for cylinder differential flow, etc.). Using a return filter with too low flow capacity or a cooler with narrow tubing will choke the flow. Always check the pressure drop vs. flow curves of filters, valves, and coolers. For example, if a filter’s datasheet shows a 1 bar drop at 100 L/min and your system can return 150 L/min, that filter is undersized. Instead, choose industrial hydraulic components engineered for low pressure drop. High-quality hydraulic flow control valves (especially pressure-compensated types) can regulate actuator speed without causing excessive backpressure spikes, because they adjust automatically to load changes. Additionally, incorporate components like accumulators or surge suppressors if needed – these can absorb pressure spikes in the return line (e.g., when valves suddenly close, mitigating water hammer effects). And, of course, ensure your main pressure relief valve is set correctly to protect against any unintended over-pressure. A relief valve set at an appropriate threshold will open and bleed off fluid to the tank if backpressure (or overall system pressure) rises too high, thus preventing damage.

Maintain Clean Filters and Fluids: A proactive maintenance program is one of the simplest ways to keep backpressure in check. As mentioned, clogged return filters are a major cause of rising backpressure. Replace or clean hydraulic filters at regular intervals before they become heavily clogged. Most systems have filter indicators – heed the warning if the indicator shows high differential pressure. Using high-quality oil and keeping it clean will delay filter clogging in the first place. Also, check strainers or any auxiliary screens in the return lines. Beyond filters, keep an eye on hoses for kinks or internal collapse (old hoses can deteriorate internally and impede flow). By ensuring the return path is free of obstructions, you prevent unnecessary pressure buildup. In summary: clean oil, healthy filters, and well-maintained return plumbing will naturally yield lower backpressure.

Use Proper Hydraulic Fluid and Manage Oil Temperature: The choice of hydraulic oil (particularly its viscosity grade) should match your operating environment to avoid viscosity-related backpressure issues. In cold environments (like Russian winters), use multi-grade or cold-temperature hydraulic oil that remains fluid at low temps, and consider installing oil heaters or warm-up cycles to avoid pushing thick oil through the system. In very hot environments (like parts of Latin America), use oil with higher viscosity index (VI) so it doesn’t become too thin at operating temperature. Also ensure your hydraulic cooling system (oil cooler) is functioning and sized correctly. An efficient cooler will dissipate the heat generated by normal pressure losses, keeping oil temperature in the optimal range. Keeping oil around its ideal temperature (often ~40–50°C for many systems) maintains consistent viscosity – not too thick, not too thin – which in turn keeps backpressure predictable. Remember: hydraulic oil temperature affects system pressure because it changes oil thickness; stable temperature control helps maintain stable backpressure.

Install Backpressure Valves Only as Needed and Adjust Properly: If your system requires a certain backpressure for stability (for example, to prevent cylinder cavitation or to balance a load), use a dedicated backpressure valve (which could be a small relief valve set to a low pressure in the return line). Set this valve to the minimum pressure that achieves the desired effect – typically just a few bar. For instance, setting a backpressure of ~5 bar might be enough to stabilize a cylinder’s motion without significantly taxing the pump. If using a flow control valve as a makeshift backpressure device (by throttling return flow), be cautious – ensure the valve is designed for such use and monitor the resulting pressure. It’s often better to use a spring-loaded relief valve for backpressure, as it will maintain a relatively constant pressure drop regardless of flow, and will open fully if pressure exceeds the setpoint. In any case, periodically check and recalibrate valve settings. Vibrations or wear can cause springs to drift over time, potentially raising the backpressure beyond what you intended.

Monitor Backpressure and System Health: Lastly, it’s hard to manage what you don’t measure. Consider installing a pressure gauge on the return line (or using sensors) to monitor backpressure during operation. Many modern hydraulic systems in industrial OEM equipment include sensors that can alert you if return line pressure goes above a threshold. By keeping an eye on this, operators can detect issues early – for example, a creeping rise in backpressure might indicate a filter that’s about to clog or a heat exchanger getting fouled. Regular monitoring ties in with maintenance: it helps you schedule service before backpressure-related problems escalate. Additionally, train your maintenance team to recognize signs of high backpressure: sluggish actuators, higher fluid temperature, unusual noises (a straining pump or whining sound can mean relief valves are opening due to backpressure).

By following these practices, you can reduce backpressure in hydraulic return lines and ensure your system runs cooler, smoother, and more efficiently. The benefits include longer component life, better energy efficiency, and improved machine reliability. In a nutshell, minimizing undue backpressure is about removing unnecessary resistance in the system – much like taking the foot off a brake that shouldn’t be on.

FAQ: Hydraulic Backpressure – Common Questions

Below is a brief FAQ section addressing some common questions about hydraulic system backpressure. These concise answers are optimized for quick reading and SEO, providing clarity on key points:

What causes high backpressure in hydraulic systems?

High backpressure is usually caused by flow restrictions or blockages in the return line of a hydraulic system. Common causes include narrow or long hoses, many elbows, or undersized fittings that create friction, as well as clogged return filters and small orifice valves that the fluid must push through. Thick, cold hydraulic oil can also cause higher backpressure due to increased resistance. Essentially, anything that impedes the free flow of return oil – from debris in the line to using the wrong size components – will cause backpressure to rise by forcing the pump to work against that resistance.

How do you reduce backpressure in hydraulic return lines?

To reduce backpressure in return lines, focus on removing restrictions and improving flow. Use adequately sized hoses and pipes (going up a diameter size can help if lines are long) to minimize friction. Limit the use of tight bends and quick-connect couplers, or choose high-flow couplers, since standard quick couplings can restrict flow. Ensure return filters and heat exchangers are properly sized and clean – replace clogged filters promptly to restore normal flow. If possible, route returns directly to tank (bypassing unnecessary valve manifolds) for high-flow components like motors, to allow free discharge. Basically, streamline the return path: smooth, short, and unhindered flow back to the reservoir will greatly lower backpressure.

Can a pressure relief valve help reduce backpressure?

Yes, a pressure relief valve can help manage backpressure, though its primary role is safety. In a hydraulic system, the main relief valve protects against over-pressure by opening when pressure exceeds a set limit. This can indirectly reduce excessive backpressure by giving the fluid an escape route if the return line pressure gets too high (for instance, due to a blockage). Additionally, a relief valve can be used as a dedicated backpressure regulator: by installing a small relief valve on the return line set to a low pressure (e.g. 5 bar), you create a controlled backpressure that never exceeds that setting. This backpressure valve ensures a constant minimum pressure for stability but will open wide if pressure rises further, thus preventing harmful buildup. In summary, while a relief valve’s main job is to protect the system, it also serves to cap the backpressure at a safe level. Always ensure the relief valve is set to the appropriate pressure and functioning correctly.

How does hydraulic oil temperature affect system pressure?

Hydraulic oil temperature affects system pressure by changing the oil’s viscosity. When oil is cold, it becomes thicker (higher viscosity), which makes it harder to flow through filters, valves, and pipes – this raises the backpressure and the system may show higher pressures until the oil warms up. You might notice sluggish movement and higher gauge readings on cold start due to this effect. As the oil heats up, it thins out (lower viscosity), flowing more easily and typically reducing backpressure in the return line. However, if oil gets too hot, it can lead to problems: extremely thin hot oil may cause internal leakage in pumps and actuators (dropping system efficiency) and can degrade, forming varnish or losing lubricity. Overheated oil is often a symptom of energy losses in the system (for example, from excessive backpressure turning into heat). That’s why maintaining an optimal oil temperature (using heaters in cold climates and coolers in hot climates) is important. In practice, keep the oil within the manufacturer’s recommended temperature range – this ensures viscosity stays in the ideal window, so the hydraulic system runs at the correct pressures without undue strain.

Where can I buy industrial hydraulic valves and components?

You can buy industrial hydraulic valves and components from a variety of suppliers and manufacturers worldwide. For instance, there are specialized hydraulic distributors in both Russia and Latin America that cater to OEMs and industrial buyers, offering products like hydraulic pressure relief valves, flow control valves, hydraulic cylinders, and cooling systems. Many buyers in countries like Mexico, Brazil, and Russia source components from global manufacturers – including reputable Chinese hydraulic component producers – due to their competitive pricing and quality. It’s advisable to look for authorized dealers or OEM-partners for brands known in the hydraulic industry. Online B2B marketplaces and manufacturer websites (for example, sourcing platforms or the websites of companies similar to Blince Hydraulic) allow you to request quotes or purchase directly. When choosing a supplier, consider factors like product specifications, compliance with international standards, shipping logistics to your location, and after-sales support. In summary, industrial hydraulic components can be purchased through local distributors in your region or directly from international manufacturers; ensure the provider is reliable and the components meet your system’s requirements for pressure, flow, and quality.