In every hydraulic system, from the smallest hydraulic pump to complex hydraulic cylinder components, one golden rule never changes — do not use water as a hydraulic fluid. At Blince Hydraulic, our engineers have worked with thousands of hydraulic components and systems, and we’ve seen what happens when people try to replace proper hydraulic oil with water: performance drops, corrosion spreads, and equipment life is dramatically shortened.

Of course, some people might argue that “water hydraulics” exist — and that’s true in very specialized industrial or marine environments. However, for conventional hydraulic components, hydraulic cylinders, and hydraulic system components, using water as the working medium causes far more harm than good. Let’s break down why, from the perspective of lubrication, corrosion, cavitation, viscosity, and temperature sensitivity.

1. Poor Lubrication Performance

One of the main functions of hydraulic oil is to lubricate the internal moving parts of every hydraulic component—from hydraulic pumps and valves to hydraulic cylinders. Oil forms a thin protective film on metal surfaces, reducing friction and preventing direct metal-to-metal contact.

Water, on the other hand, has extremely poor lubricating properties. When used inside hydraulic cylinder components or gear pumps, the absence of oil film causes rapid wear, scoring, and even seizing of parts. Over time, the entire hydraulic component service life drops drastically.

2. Corrosion and Seal Degradation

Water contains oxygen and impurities that easily react with metal. Continuous exposure leads to rust, pitting, and degradation of precision surfaces inside hydraulic components. Moreover, rubber seals and gaskets—key components of a hydraulic cylinder—are not compatible with water. They swell, harden, or deteriorate, eventually causing internal leakage and system inefficiency.

That’s why professional hydraulic component suppliers like Blince Hydraulic always recommend using premium hydraulic fluids with anti-corrosion additives, not water.

3. Cavitation Damage

Cavitation occurs when vapor bubbles form and collapse violently inside a hydraulic system component. Because water’s boiling point is much lower than that of hydraulic oil, it vaporizes easily under high pressure and temperature. When these bubbles implode, they create micro-shockwaves that can pit and erode metal surfaces inside pumps, valves, and hydraulic cylinders components.

This microscopic erosion gradually destroys the precision fit of components in a hydraulic system, lowering system efficiency and leading to expensive repairs.

4. Low Viscosity and Leakage

Viscosity is crucial to how hydraulic components generate and maintain pressure. Hydraulic oil’s viscosity ensures proper sealing of internal gaps, smooth motion, and energy transmission. Water, however, is too thin. Its low viscosity means it cannot maintain adequate sealing between piston and cylinder walls, resulting in internal leakage, pressure loss, and lower torque output.

In short, your complete hydraulic component service will never perform as designed if water replaces oil.

5. Extreme Temperature Sensitivity

Water freezes at 0°C and evaporates quickly at high temperatures. In cold climates, frozen water expands and cracks hydraulic system components such as valves and cylinders. In hot environments, vaporization leads to pressure fluctuations and cavitation.

By contrast, quality hydraulic oils—like those recommended by hydraulic component specialists—are formulated to perform across a wide temperature range. They contain additives that stabilize viscosity, resist oxidation, and protect against thermal stress.

6. Special Cases: Water-Based Hydraulics

It’s true that certain niche systems—such as environmentally friendly or fire-resistant hydraulics—use water-glycol mixtures. But even in those designs, the fluid is heavily treated and controlled, and the hydraulic components are purpose-built to handle corrosion, lubrication, and viscosity challenges.

For most commercial and industrial applications, standard hydraulic cylinder components and hydraulic components suppliers specify only hydraulic oil-based systems.

Conclusion: Oil and Hydraulics Are Made for Each Other

In summary, replacing hydraulic oil with water in hydraulic components and systems leads to inadequate lubrication, corrosion, cavitation, leakage, and failure under temperature extremes. The efficiency, safety, and lifespan of your hydraulic system components depend on using the right fluid — hydraulic oil.

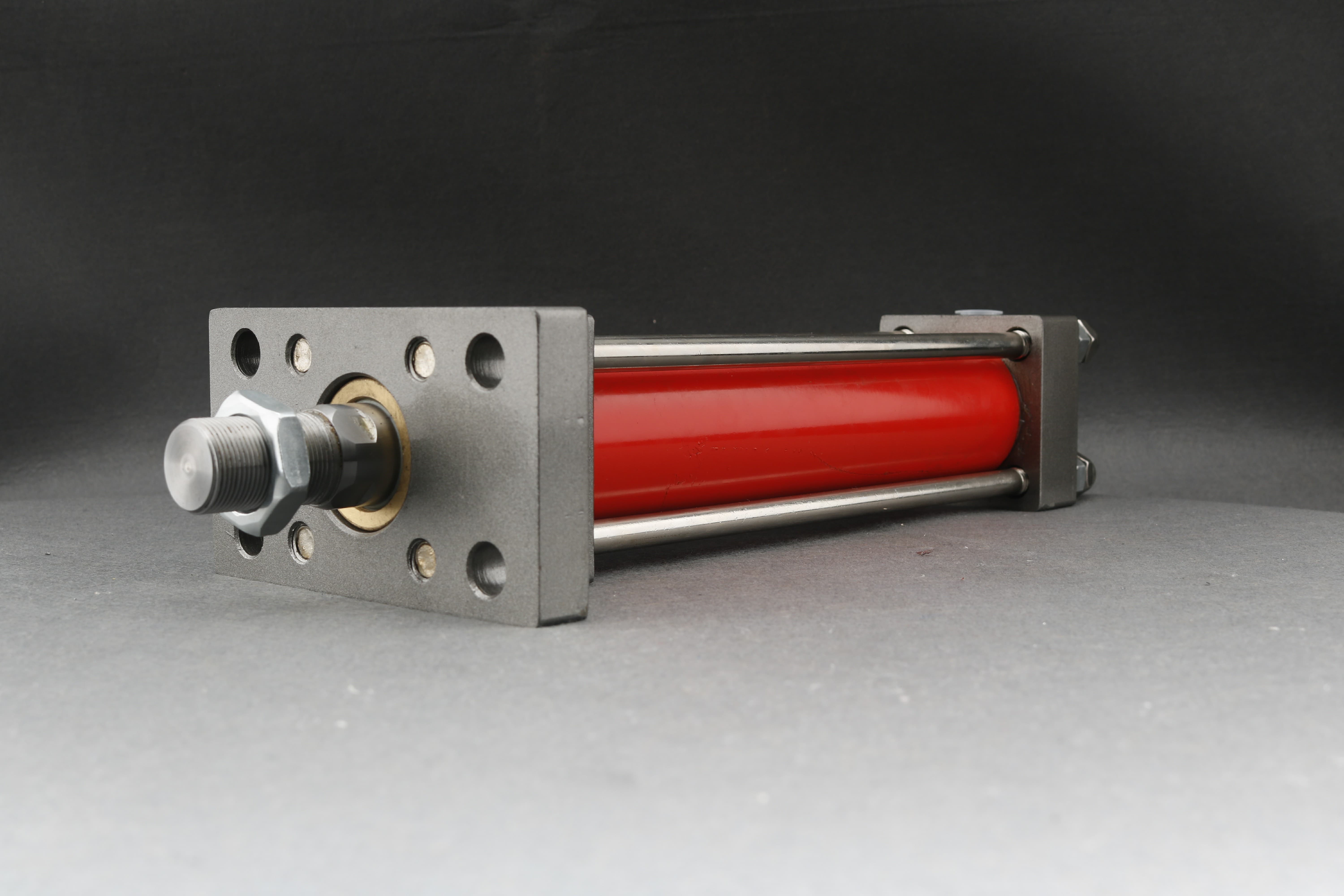

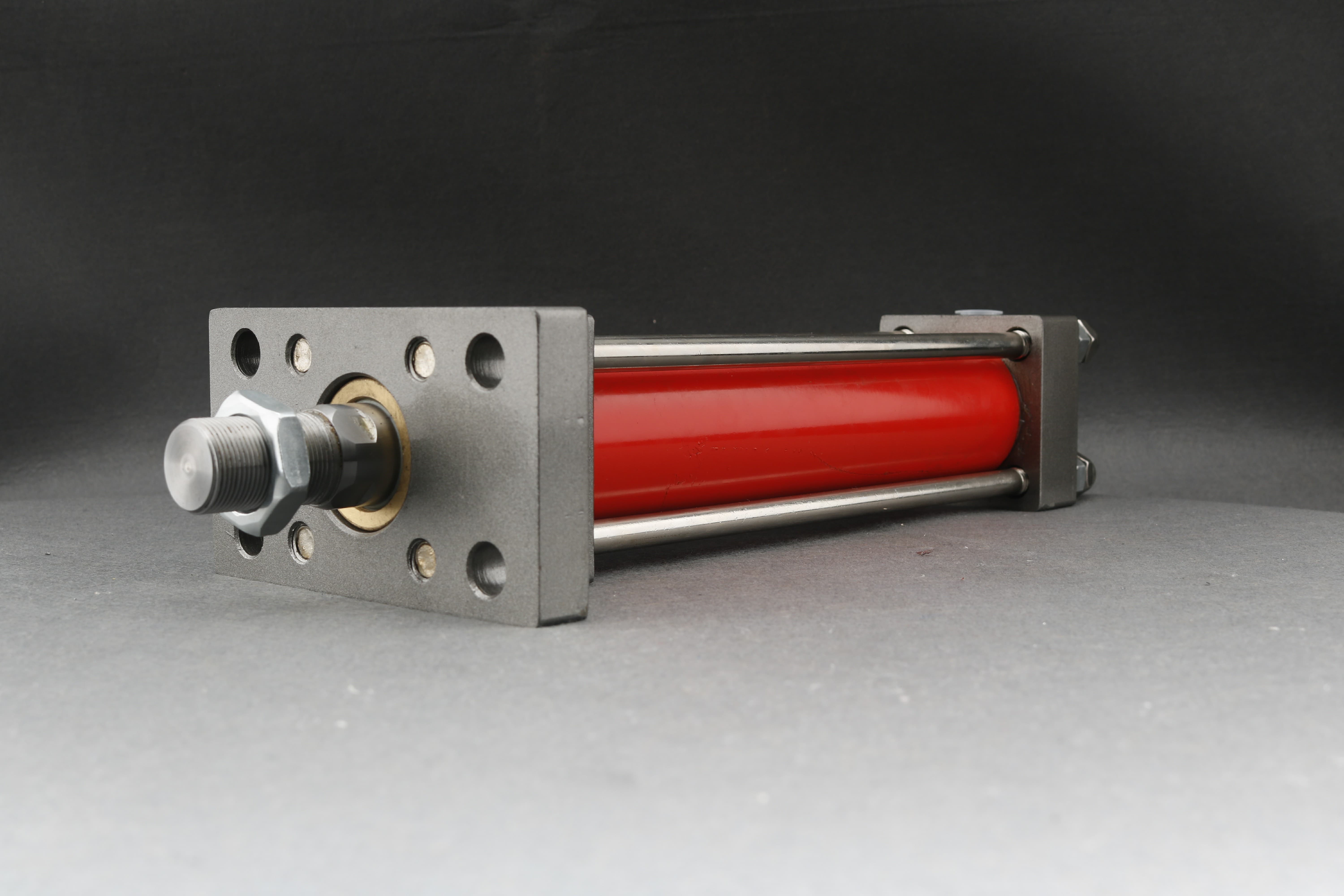

At Blince Hydraulic, we are committed to delivering durable, high-performance hydraulic components, including hydraulic cylinder components, pumps, valves, motors, and custom system solutions. As professional hydraulic component suppliers and hydraulic component specialists, we provide a complete hydraulic component service—from design and manufacturing to testing and after-sales support—to keep your system reliable under any condition.

1. Can hydraulic components run on water instead of oil?

No. Standard hydraulic components are not designed to operate with water as the working fluid. Water lacks the lubrication, viscosity, and temperature stability required for hydraulic system components, leading to wear, corrosion, and pressure loss.

2. What happens if water enters a hydraulic system?

If water contaminates your hydraulic components and systems, it can cause rust, cavitation, and seal damage. Even a small amount of water can reduce system efficiency, shorten the lifespan of hydraulic cylinder components, and increase maintenance costs.

3. Are there any hydraulic systems that use water safely?

Yes, but only specially designed water-based or water-glycol systems. These are engineered with corrosion-resistant materials and unique hydraulic component designs. Normal hydraulic component suppliers do not recommend using water in traditional oil-based systems.

4. Why is hydraulic oil better than water?

Hydraulic oil provides excellent lubrication, maintains stable viscosity, and protects hydraulic components from corrosion and wear. It ensures consistent performance of all components in a hydraulic system, including pumps, valves, and cylinders, even under extreme conditions.

5. How can I maintain my hydraulic components properly?

Work with trusted hydraulic component specialists like Blince Hydraulic. Regularly inspect seals, replace hydraulic oil on schedule, and use only manufacturer-approved fluids. Blince offers complete hydraulic component service, including testing, repair, and performance optimization.

6. Where can I find reliable hydraulic component suppliers?

Blince Hydraulic is a professional hydraulic component supplier providing a full range of hydraulic cylinder components, valves, motors, and custom hydraulic system components. Our hydraulic component services cover everything from system design to after-sales maintenance.