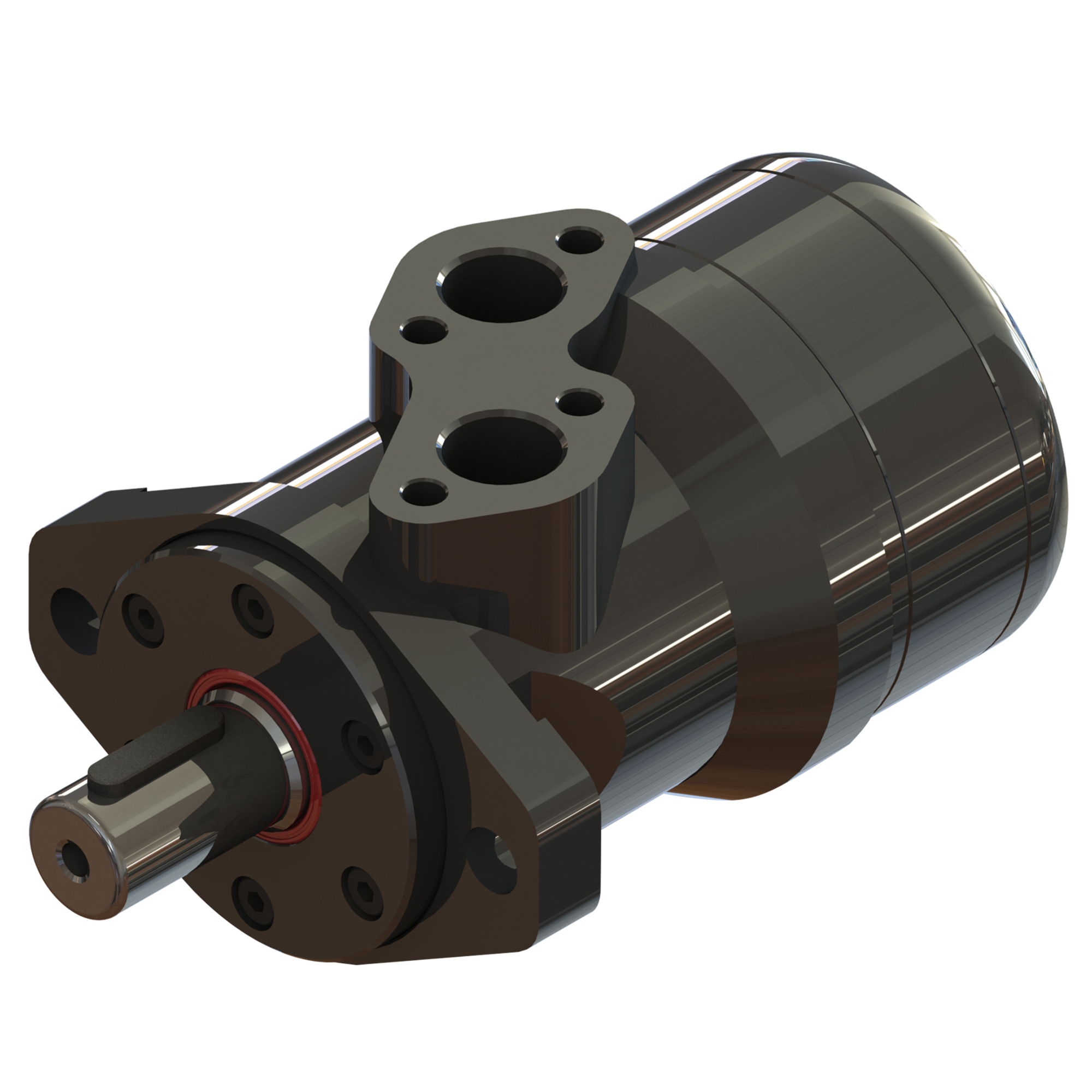

Hydraulic motors are critical rotary actuators in fluid-power systems. They convert pressurized hydraulic fluid into mechanical rotation. Proper hydraulic motor maintenance is essential, because both neglect (long idle periods) and overuse (excessive load) can cause failures. This article examines how long-term idleness and overload operation each damage hydraulic motors, and outlines maintenance practices and failure‐prevention strategies.

How Hydraulic Motors Work

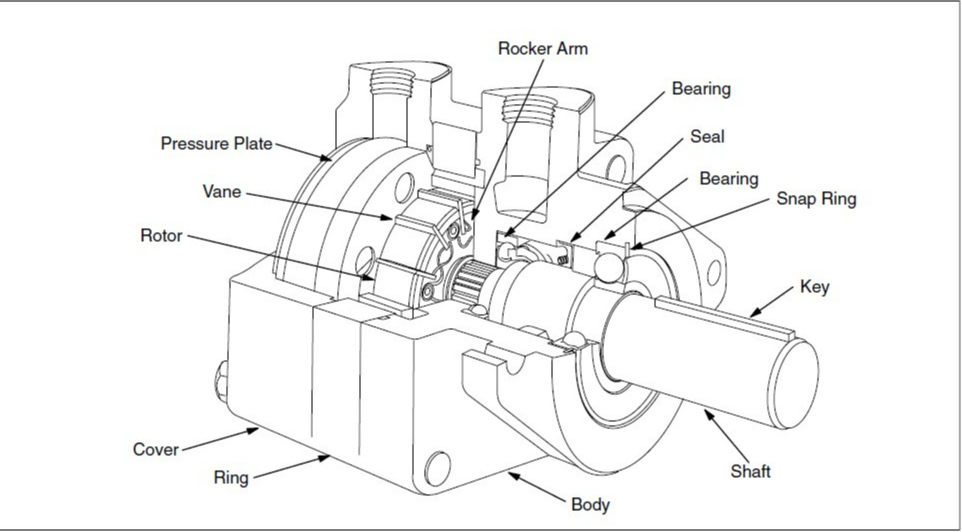

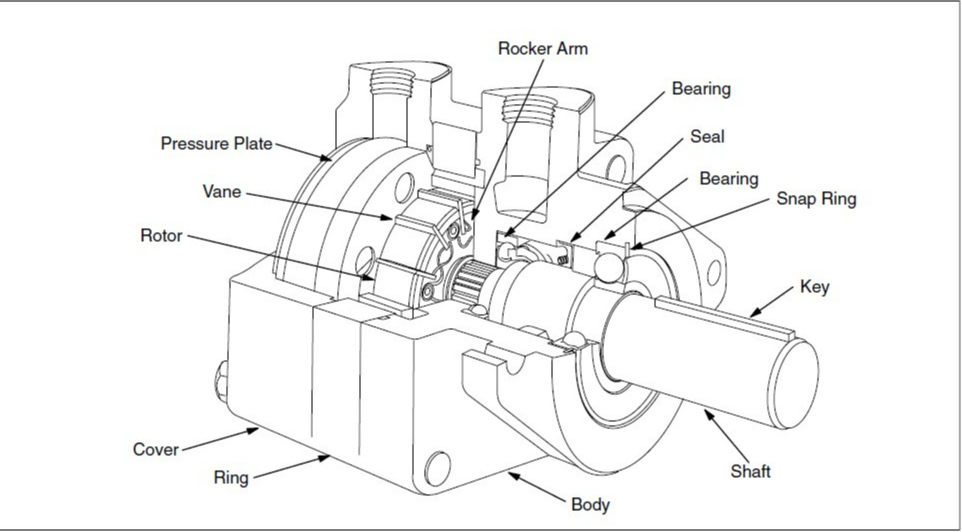

A hydraulic motor is essentially an energy‐conversion device that transforms fluid pressure into rotary mechanical energy. Pressurized oil from the pump enters the motor housing and pushes on internal elements – typically pistons, gears, or vanes – causing the output shaft to turn. In general, the motor’s speed is proportional to the fluid flow rate, while its torque output is proportional to the system pressure. In other words, more flow drives a faster speed, and higher pressure allows higher torque. Because of this, hydraulic motors can deliver very high torque at low speeds. Understanding this principle is key to preventing damage: running a motor beyond its rated flow or pressure will cause strain on components and should be avoided.

Effects of Long-Term Idleness on Hydraulic Motors

Ironically, leaving a hydraulic motor unused for a long time can lead to problems almost as serious as overloading it. In an idle motor, trapped hydraulic fluid and air can promote internal corrosion. Moisture in stagnant oil often condenses on metal parts, causing rust or microbial growth that degrades components. For example, if ports or reservoir breathers are not sealed, ambient moisture will enter and create rust spots; seals may harden or crack from lack of lubrication. Over months of inactivity, seals can stick or shrink and bearings may lose their protective oil film, leading to leaks or even a locked‐up motor. Common idle‐related issues include:

Corrosion and rust. Water or vapor in the fluid can trigger oxidation of internal parts. Bacterial or microbial growth in old oil can also form acids that eat away at surfaces.

Seal degradation. Lack of motion and clean fluid causes seals to dry out, harden or tear, allowing hydraulic leaks.

Oil degradation. Hydraulic oil can oxidize or become contaminated over time. Stale or dirty oil loses lubricating properties and can harm precision fits.

Sticking of moving parts. Without periodic movement, pistons, vanes or splines may seize or develop flat spots.

Preventive maintenance: If a motor must be stored or idle, flush it with rust‐inhibiting oil, plug or cap all ports, and wrap it to exclude moisture. Rotate the shaft by hand occasionally and, if possible, cycle fresh hydraulic fluid through the system every few weeks. Following a motor maintenance schedule that includes periodic exercise and inspection even when “out of service” will mitigate idle‐damage risks.

Consequences of Overload Operation

Operating a hydraulic motor beyond its design limits produces another set of failures. Excessive load (over‐torque or over‐pressure) quickly overheats the motor and fluid. High temperature accelerates oil oxidation and breaks down additives, causing the oil to thicken or become acidic. Over time, overheating damages seals and bearings. For example, running a motor continuously under heavy load will make the fluid absorb more water and oxidize faster, which in turn corrodes metal parts and seals.

Mechanical stress from overload causes accelerated wear and even immediate failures. Long periods of high pressure or shock loads wear out bearings, gears and couplings; shafts can bend or break; and housings can crack under extreme pressure. In fact, heavy‐duty applications often cause noise increases and power loss because internal parts wear out when lubricating conditions are poor. Key overload‐related failure modes include:

Overheating: Sustained overload raises oil and motor temperature, degrading fluid and weakening seals and components (a runaway effect).

Mechanical wear and fatigue: Excess torque stresses bearings, splines and gears. High loads over time “polish” surfaces or cause cracking and pitting.

Hydraulic shock and cavitation: Sudden pressure spikes (for example, when equipment hits a hard stop) generate shock loads. Vapor bubbles collapsing in the fluid (cavitation) create microscopic “hammer” effects inside the motor, damaging surfaces.

Structural failure: Extreme pressure beyond the motor rating can shear shafts or burst the housing if relief mechanisms fail.

To prevent overload damage, hydraulic systems use pressure relief valves or electronic load sensing to limit torque. Always operate the motor within its rated pressure and flow. If a motor overheats or displays unusual noise under heavy use, stop and inspect it immediately. Proper failure prevention strategy includes selecting the correctly sized motor for the application and setting relief valves to prevent over‐pressure situations.

Common Hydraulic Motor Failure Causes

Whether from idleness or overload, many hydraulic motor failures stem from a handful of root causes. In practice, the top failure causes include contaminated fluid, air entrainment, poor lubrication, excessive heat, and mechanical wear. Contaminants (dirt, metal particles, or water) in the oil abrade moving parts and clog clearances. Air bubbles in the system can cause cavitation and erratic performance. Exceeding temperature or pressure limits leads to seal failures and material fatigue. Likewise, misalignment of couplings, bad bearings, or loose fittings introduce vibration and leaks. In short, the failure causes often cited are: contamination, inadequate maintenance, and operating outside specifications. In many cases, neglecting routine hydraulic maintenance tasks like filter changes or fluid checks allows small issues to become catastrophic.

Troubleshooting tips: If a motor runs slowly or loses power, check for clogged suction lines or low oil (which starves the pump). Unusual noise often signals internal wear or airflow (from leaks). Visible fluid leaks indicate seal or fitting failures and should trigger an inspection. By combining good design (overload protection, proper components) with vigilant maintenance, most failure causes can be prevented.

Maintenance Schedule and Best Practices

A well-planned maintenance schedule is the best defense against both idleness and overload damage. Key practices include:

Regular oil and filter maintenance: Replace hydraulic oil according to the manufacturer’s schedule, and change or clean filters frequently. Clean oil keeps seals and components lubricated and prevents abrasives from accelerating wear.

Frequent inspections: At least daily or weekly, check fluid levels and refill to keep proper oil level. Low fluid can cause cavitation and overheating. Inspect filters, breathers and oil for contamination or water. Every few weeks, visually inspect hoses, fittings, and seals for signs of wear or leakage. Quarterly or semiannual checks should include bearing endplay and shaft alignment.

Temperature monitoring: Track operating temperature. High temperatures indicate cooling or airflow issues; low (or very high) temperatures can be signs of systemic problems.

Environmental control: Operate and store equipment in a clean, dry area. Keep ambient humidity and temperature within recommended ranges. As noted in storage guidelines, using rust inhibitors and sealing unused units is important.

Use OEM parts and correct oil: Always use hydraulic oil and replacement parts that meet the motor maker’s specifications. Mixing oil types or using generic seals can accelerate failure.

Following a documented motor maintenance schedule – for example, monthly oil analyses, biweekly filter checks, quarterly full inspections – will greatly improve reliability and reduce downtime. By embedding these preventive measures into routine maintenance, organizations can minimize unplanned repairs and extend motor life.

FAQ

Q: What is a hydraulic motor?

A: A hydraulic motor is a type of rotary actuator in a hydraulic system. It converts the pressure and flow of hydraulic fluid into rotational mechanical power. In practice, the pump pressurizes oil, and the motor’s internal vanes, pistons or gears use that pressure to spin the output shaft.

Q: How does a hydraulic motor work?

A: In simple terms, when pressurized oil enters the motor, it acts on internal components (such as pistons or vanes) that force them to rotate around a shaft. The motor’s speed is controlled by the oil flow rate, and the torque it generates is controlled by the system pressure. Thus, more flow yields faster rotation, and more pressure yields higher torque.

Q: What causes hydraulic motor failure?

A: Common causes include contaminated oil, overheating, cavitation (air bubbles collapsing), lack of lubrication, and excessive loads. Dirt or water in the fluid scours internal parts, extreme temperatures degrade oil and seals, and air in the system can trigger vibration and shock. Operating the motor above its pressure/torque ratings is also a frequent cause of bearing or seal failure.

Q: How can hydraulic motor failure be prevented?

A: Most failures can be prevented with good maintenance and proper usage. Key steps are: keep the hydraulic fluid clean (change oil/filters on schedule), avoid running hotter or heavier than the motor’s rating, bleed out any trapped air, and maintain proper fluid levels. Using pressure relief valves and monitoring system temperature are also critical preventive measures. In practice, a hydraulic motor maintenance schedule that includes regular inspections will catch problems early.

Q: What maintenance does a hydraulic motor need?

A: Routine maintenance includes checking and changing the hydraulic oil, replacing filters, inspecting and replacing seals, and verifying hose and fitting integrity. A typical schedule might be: daily visual checks (fluid level, leaks), weekly filter checks, quarterly bearing and shaft inspections, and annual internal component service. Maintaining the correct oil type and viscosity is also important for preventing wear.

Q: How is a hydraulic motor repaired?

A: Repair usually involves disassembling the motor to inspect wear parts. Common repairs include replacing worn seals, bearings, pistons or vanes. If a motor has lost significant wear tolerances or the housing is damaged, it may need a full overhaul or replacement. Always use genuine replacement parts. After repair, the motor must be tested for correct pressure and flow characteristics before returning to service.

Q: Can a hydraulic motor be damaged by sitting idle?

A: Yes. Leaving a hydraulic motor idle for long periods without maintenance can lead to seal hardening, oil oxidation, and corrosion inside the motor. To prevent this, equipment should be run or at least manually turned periodically, and stored with protective oil films and sealed ports