Hydraulic steering units—often called hydraulic steering control units, hydrostatic steering units, or orbital steering units (Orbitrol‑type)—are the “command center” of a hydraulic steering system. They turn a small steering wheel input into a precisely metered oil flow that moves a steering cylinder, making heavy machines easy to steer under load. This matters especially for tractors, harvesters, loaders, forklifts, and special vehicles working long shifts in Russian‑speaking Eurasian markets and Spanish‑speaking Belt & Road project regions, where reliability, serviceability, and correct pump matching often decide total operating cost.

What confuses many buyers and engineers is that steering units are described in two overlapping ways: center type (open center, closed center, load sensing) and feedback behavior (reaction vs non‑reaction). Danfoss—a leading manufacturer of hydraulic steering units—explicitly lists common variants as open center non‑reaction, open center reaction, closed center non‑reaction, and load sensing (LS).This guide explains each type with definitions, working principles, pros/cons, and typical applications, while also aligning terminology with supplier category namingsuch as Blince’s Hydraulic Steering Control Unit product category and BZZ series hydraulic steering control units.

Hydraulic steering unit basics and key vocabulary

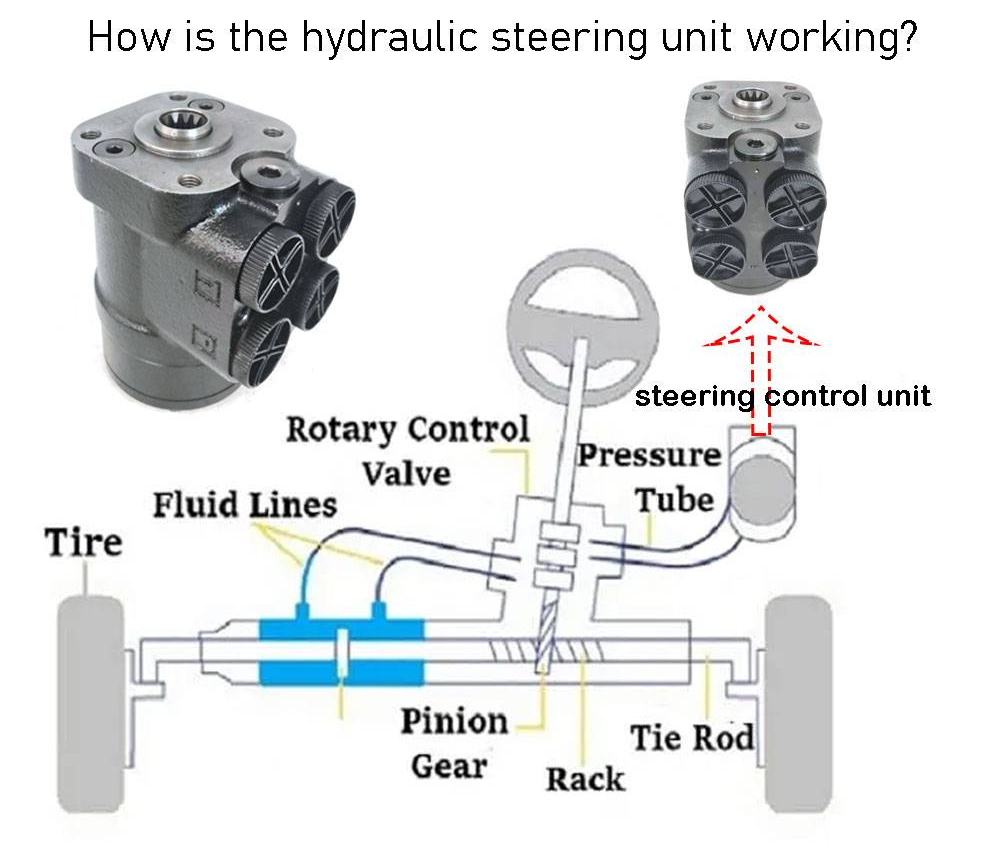

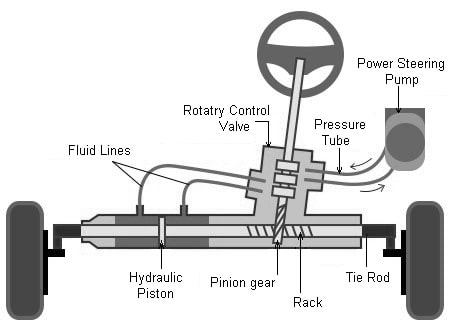

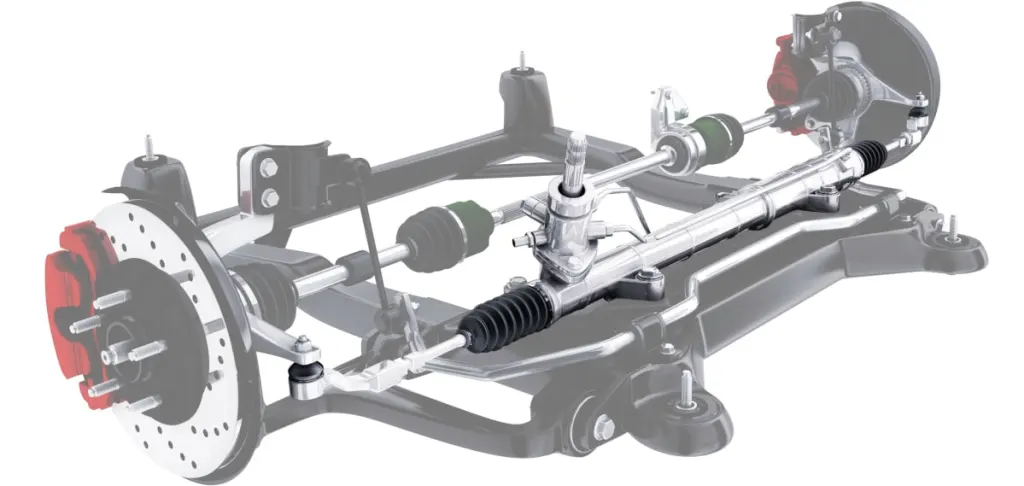

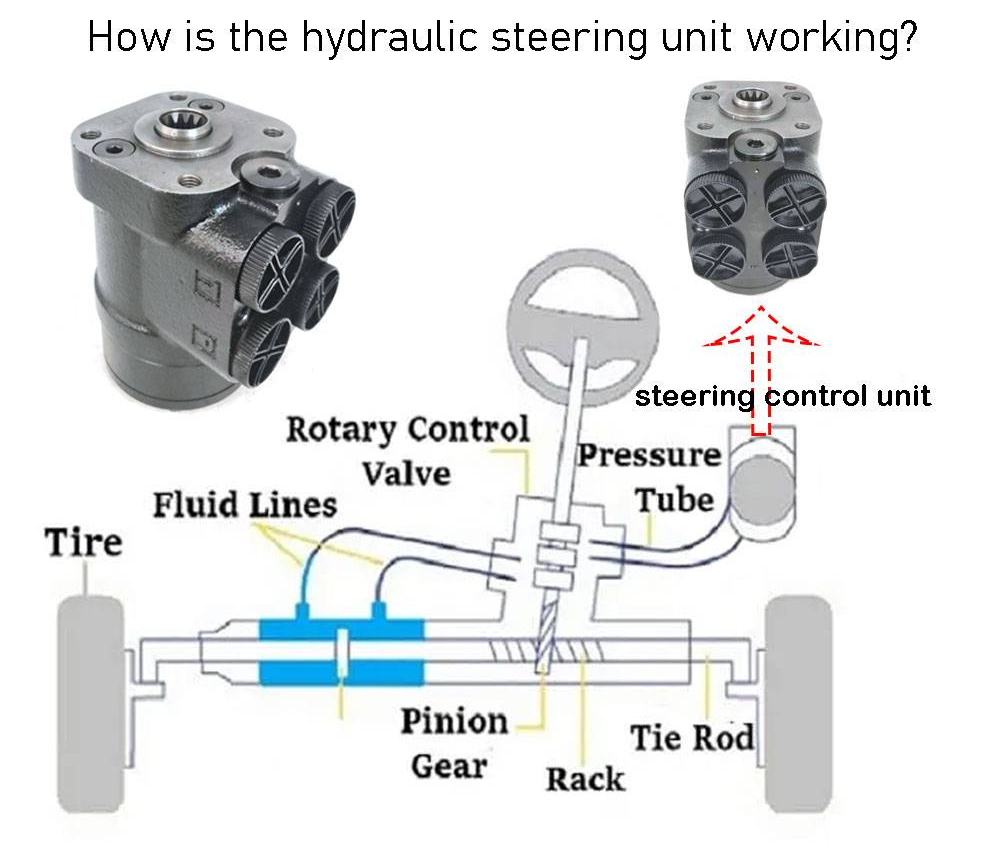

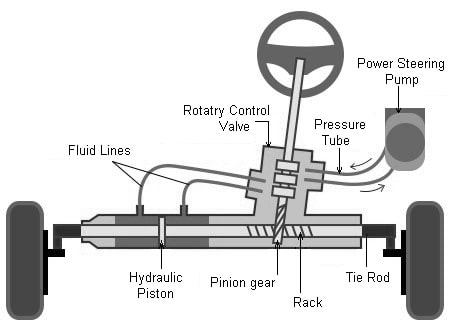

A typical hydrostatic steering unit combines a rotary control valve (spool/sleeve valve with a torsion element) and a rotary metering element (often a gerotor/rotary meter). When you turn the steering wheel, the valve meters flow proportionally and directs oil to the left or right cylinder port; when you stop, the unit returns to neutral and holds or manages flow depending on its configuration. Danfoss technical literature describes these units as “hydrostatic steering units” offered in multiple variants for different hydraulic circuits and steering behaviors.

In circuit diagrams and on the steering unit housing, these ports are the ones you will see most often:

P (Pressure / Pump): supply from pump or from a priority valve

T (Tank / Return): return to reservoir

L and R (Left / Right work ports): to the steering cylinder chambers (sometimes labeled A/B)

LS (Load Sensing): signal port in LS systems (only present on LS steering units)

Many steering unit families can also be ordered with built‑in valve functions—such as pressure relief, shock/suction valves at the work ports, and check/non‑return valves—depending on model and configuration. Danfoss notes optional port connection standards (ISO/SAE/DIN) and integrated valve functions across many types, which is important for export machinery and cross‑border spare parts sourcing.

Below is a simplified “mental model” diagram for how center types differ in neutral:

OPEN CENTER (neutral): P -----> T (continuous flow path open)

L/R: typically held/blocked (depends on reaction design)

CLOSED CENTER (neutral): P X (blocked / no through-flow)

L/R: typically held/blocked (work ports managed by design)

LOAD SENSING (neutral): P: supplied via priority/LS pump logic

LS -----> T (LS signal vented in neutral)

This neutral behavior is the core of why pump matching is non‑negotiable: open center expects continuous flow from a fixed pump, while closed center/LS are designed around variable delivery or priority‑controlled delivery.

Open center steering units and open center steering systems

Definition and system intent

An open center steering unit has an open connection between pump and tank in the neutral position, and it is used in open center steering systems that typically use a fixed displacement pump. Danfoss states this directly: open center steering units have an open pump‑to‑tank connection in neutral, and open center systems use fixed displacement pumps.

Hydromot uses similar wording: “Open Center” means the unit is intended for open systems, and in neutral there is an open connection between pump and tank.

Working principle

In neutral, pump flow passes through the steering unit back to tank, keeping system pressure relatively low. When the operator turns the steering wheel, the rotary valve meters and directs flow to L or R, moving the cylinder and turning the wheels. This architecture provides immediate steering response once wheel rotation begins, and Danfoss emphasizes “immediate reaction” as a feature of open center steering systems with open center steering units.

Advantages

Open center steering is often chosen for robustness and straightforward maintenance:

Simpler circuit integration with fixed displacement pumps (fewer control elements than LS/closed center).

Proven suitability for tractors, harvesters, forklifts, contractor machines, and special vehicles in open‑circuit steering arrangements.

Wide commercial availability in common “ON/OR” variants (open center non‑reaction / open center reaction).

Disadvantages

The core tradeoff is energy and heat:

A fixed pump supplies flow continuously; in neutral, that flow returns to tank instead of doing useful work, which increases fuel consumption and heat load over long duty cycles. (This is an inherent implication of “open connection between pump and tank” in neutral.)

In multi‑function machines, open center steering without priority management can be less efficient than LS architectures designed to share pumps across circuits.

Typical applications

Open center steering units remain common in machines built around fixed displacement pumps and cost‑sensitive configurations: older tractors, basic agricultural machines, forklifts, and simple contractor vehicles. Danfoss lists tractors, harvesters, forklifts, and contractor/special vehicles as applications for steering unit families offered in open center variants.

Closed center steering units and closed center steering systems

Definition and system intent

A closed center steering unit is blocked at the P (pump) port in neutral, and closed center steering systems require variable oil flow (i.e., variable delivery/controlled supply rather than continuous open‑return flow). Danfoss describes closed center steering units exactly this way: P is blocked in neutral, and variable oil flow is required. 5

This definition is the most important compatibility rule in the entire topic: closed center units are not simply “a different label”—they assume a different pump/supply strategy than open center.

Working principle

In neutral, the steering unit prevents through‑flow at the pump port (P is blocked), so flow demand drops to near zero. When steering occurs, the unit meters and directs oil to L or R in proportion to steering input, and the pump/compensation arrangement supplies only what is needed for steering.

Advantages

Closed center steering is often selected for efficiency and thermal control:

Reduced neutral/idle flow losses because P is blocked in neutral (less constant recirculation to tank than open center).

Better alignment with variable delivery strategies common in modern machinery hydraulic design (especially where multiple circuits share a pump via compensation logic).

Disadvantages

The tradeoff is system sophistication and the cost of correct matching:

Requires a compatible supply strategy (“variable oil flow”)—commonly a pressure‑compensated or flow‑and‑pressure‑compensated pump or an equivalent controlled supply arrangement.

Mis‑matching a closed center steering unit to an open‑center fixed pump circuit can cause unstable steering performance or excessive heat/pressure behavior because the unit is designed to block P in neutral.

Typical applications

Closed center steering units are used in modern equipment architectures where steering is part of a controlled hydraulic “ecosystem,” often with higher expectations for efficiency and thermal stability. Danfoss includes closed center variants in its steering unit availability lists alongside open center and LS configurations.

Load sensing steering units and LS priority steering circuits

Definition and what makes LS unique

A load sensing steering unit includes an extra LS (load sensing) connection that transmits a load pressure signal from the steering unit to a priority valve and/or an LS pump. Danfoss explains that LS steering units have this extra LS port; the LS signal controls oil flow from the priority valve and/or LS pump to the steering unit, and the LS connection is open to tank when the steering unit is in neutral.

Hydromot summarizes the system‑level concept clearly: in LS steering units, the steering system and working hydraulics can be supplied by a common pump, and a priority valve ensures steering has first priority.

Working principle

In a typical LS steering circuit, the steering unit sends an LS signal proportional to steering demand. That signal shifts the priority valve (or commands an LS pump) so steering receives guaranteed flow first; excess flow is made available to other circuits (implements, booms, auxiliary functions). Eaton/Char‑Lynn literature highlights key benefits of this architecture: only the flow required by the steering maneuver goes to steering, unused flow is available for auxiliary circuits, and the steering circuit maintains flow/pressure priority.

Danfoss also distinguishes load sensing static vs load sensing dynamic steering systems. In Danfoss’ definition, dynamic LS systems have constant flow in the LS connection toward the steering unit even when the steering unit is in neutral, while static systems do not (this distinction matters when selecting the correct priority valve type).

Advantages

LS steering is widely used in advanced mobile hydraulics because it improves both steering assurance and efficiency:

Steering priority is engineered into the circuit via the LS signal and priority valve logic.

Improved overall machine efficiency because unused flow is allocated to auxiliary circuits rather than dumped across relief or returned pointlessly to tank.

Strong fit for multi‑function machines and upgrade projects where a single pump must support steering plus implements.

Disadvantages

LS performance depends on correct system design:

More plumbing and more components (LS line, priority valve sizing/matching, correct control pressure strategy). Eaton explicitly notes that steering control unit and priority valve must be matched to achieve desired steering rates and stability.

Static vs dynamic LS choices can be misapplied if the installer is not careful, leading to unstable signals or slow response.

Typical applications

LS steering is common in modern tractors, harvesters, and contractor machines where steering must remain reliable even while other hydraulic functions operate. Danfoss steering unit families include LS variants, and Eaton/Char‑Lynn describes LS steering in the context of shared pumps and priority circuits.

Reaction vs non-reaction steering units and what “feedback” really means

Definitions

Reaction steering units transmit external wheel forces back to the steering wheel: Danfoss defines reaction as “any external forces acting on the steered wheels result in a corresponding movement of the steering wheel when the driver is not steering.”

Non-reaction steering units block that behavior: Danfoss defines non‑reaction as no corresponding steering wheel movement when the driver is not steering. Hydromot aligns this idea under the term “Non Load Reaction,” stating that external forces acting on the wheels do not trigger rotational movement on the steering wheel when the steering unit is in neutral.

What changes inside the unit

Reaction vs non‑reaction is not just “feel”; it changes how wheel‑induced pressure and displacement are managed at the work ports. In reaction designs, wheel forces can drive oil back through internal paths, which rotates the steering wheel (road feel / kickback). In non‑reaction designs, the steering unit is configured to prevent wheel forces from back‑driving the steering wheel when in neutral, improving operator comfort and stability during impact loads.

A simplified conceptual diagram:

Reaction type: Cylinder pressure change -> internal feedback -> steering wheel moves

Non-reaction type: Cylinder ports isolated/managed -> steering wheel does NOT move

Advantages and disadvantages

Reaction steering provides informative feedback but can be tiring; non‑reaction improves comfort but reduces tactile information.

For engineers, the key is to choose based on safety, operator expectations, and how much “kickback” is acceptable for the machine category. Danfoss’ product availability lists show both reaction and non‑reaction options within the same steering unit families, indicating that this is an intentional design choice rather than a niche feature. 1

Typical applications

Reaction steering is often favored where operator feedback improves controllability on rough terrain or during demanding maneuvering (e.g., some agricultural and off‑road applications).

Non-reaction steering is widely used where comfort and reduced kickback are priorities (common across many heavy machines), and it is explicitly one of the most common variants offered in open center, closed center, and LS configurations.

A practical selection checklist

Start with your pump and machine architecture, then refine:

Confirm the hydraulic center requirement: open center vs closed center vs LS. 5

Decide on feedback behavior: reaction vs non‑reaction based on operator preference and machine environment. 4

Specify ports and standards: ISO/SAE/DIN port options can affect field serviceability and hose fittings in export projects. 1

Select integrated valve functions as needed (relief, shock/suction valves, check valves), especially for heavy impacts and safety. 3

Check relevant steering safety requirements for wheeled earth‑moving machinery: ISO 5010:2019 specifies steering system tests and performance criteria for wheeled, ride‑on earth‑moving machinery and covers hazards related to control and travelling functions.

FAQ

What is the best hydraulic steering unit type for machinery fleets in Russian-speaking Eurasia?

For many legacy tractors and simple utility machines, open center steering remains common because it matches fixed displacement pumps and uses an open pump‑to‑tank connection in neutral.

For newer machines that share a pump between steering and working functions, load sensing steering is often the preferred architecture because a priority valve ensures steering priority while allocating unused flow to auxiliary circuits.

In Spanish-speaking markets, how do I explain “open center steering” vs “closed center steering” simply to customers?

A practical explanation consistent with manufacturer definitions is: open center means the circuit allows pump flow back to tank in neutral, while closed center means the supply (P) is blocked in neutral and the system requires variable oil flow.

This phrasing is often easier for bilingual sales teams, because it focuses on what happens when driving straight rather than on internal valve geometry.

When should a project choose reaction steering vs non-reaction steering for rough sites (mining, forestry, road building)?

If the operator benefit of “road feel” is important and some steering wheel movement from external wheel forces is acceptable, reaction steering provides that behavior by design.

If comfort, reduced kickback, and steering stability are more important—common in heavy work cycles—non‑reaction steering prevents wheel forces from rotating the steering wheel when the driver is not steering.

What does “load sensing steering” mean in one sentence for local SEO in Latin America and Eurasia?

It means the steering unit has an LS signal port that sends a load pressure signal to a priority valve and/or LS pump, so steering gets the flow it needs first and unused flow can serve other hydraulics.

How do Blince BZZ series steering control units fit into these categories?

Blince markets its BZZ series hydraulic steering control units under the Hydraulic Steering Control Unit (SCU) category and describes them for low-speed, heavy-duty vehicles with low control torque and load‑independent response.

When building specifications or content pages, you typically pair that product naming with the correct circuit type terminology (open center / closed center / LS, reaction / non‑reaction) from manufacturer definitions to avoid misapplication.