Hydraulic cylinders are the muscle behind heavy machinery – from construction excavators in South America to mining trucks in Central Asia, these cylinders lift, push, and support immense loads every day. When a hydraulic cylinder bursts (experiences catastrophic failure), it can lead to sudden downtime, costly repairs, and serious safety hazards. Industrial buyers and machinery manufacturers – especially those in Spanish-speaking countries like Argentina, Chile, Peru, and Russian-speaking Belt and Road regions – must understand why these failures happen and how to prevent them. In this comprehensive guide, we’ll explain the most common causes of hydraulic cylinder bursting (cylinder failure) and offer practical insights for maintaining high-pressure hydraulic systems. Manufacturers such as Blince Hydraulic design heavy-duty industrial cylinders to withstand extreme conditions, but proper usage and maintenance are equally critical to avoid failure.

Common Causes of Hydraulic Cylinder Failure

Even high-quality industrial hydraulic cylinders for heavy equipment can fail if operating conditions turn unfavorable. Below we detail the primary causes of cylinder bursting – including system overpressure, fatigue damage, oil contamination, and design or installation flaws – along with real-world examples and warnings relevant to high-pressure industrial environments.

System Overpressure and Pressure Spikes

One leading cause of cylinder burst is excessive system pressure – when the hydraulic pressure exceeds the cylinder’s design limits. Hydraulic cylinders are rated for a maximum pressure, with a safety margin for short spikes. However, if pressure surges well beyond that limit, the cylinder’s metal and seals can yield or rupture. Overpressure often occurs due to sudden load shocks or improper relief valve settings. For example, imagine a wheel loader rated for 3000 PSI lifting a full bucket: hitting a bump can cause pressure to spike 2–3 times above working pressure, potentially reaching 6000–9000 PSI – far above what a 3000 PSI-rated cylinder can handle. Such spikes can bulge or burst the cylinder barrel, dislodge end caps, or even bend the piston rod and mounting pins. The results are instant and catastrophic: high-pressure oil sprays, loss of load control, and destroyed cylinder components.

Warning: Overpressure bursts often happen without warning, turning the cylinder into a safety hazard. To prevent this, always use correctly set relief valves and avoid overloading equipment. Regularly check that the hydraulic system’s pressure stays within the manufacturer’s specifications – operating outside those specs creates dangerous conditions. In high-pressure systems (common in heavy equipment like mining drills or press machines), a single pressure spike can crack a weld or split a cylinder seam. Never bypass or “plug” relief valves, and ensure accumulators or dampers are in place to cushion shock loads. High-pressure hydraulic system maintenance is key: a failed safety valve or blocked line can allow pressure to skyrocket, so inspections and proper circuit design save lives and equipment.

Fatigue Damage and Material Failures

Not all cylinder failures happen in an instant; many develop over time due to fatigue damage. Hydraulic cylinders undergo repeated pressure cycles and stress reversals as machinery operates. Over months and years of heavy use – for instance, a crane cylinder lifting thousands of loads or an excavator arm cycling all day in a Chilean mine – microscopic stresses accumulate in the metal. Tiny cracks can form in the cylinder tube, welds, or rod over time. With each pressure cycle, these cracks grow until one day the structure gives way. Fatigue failure often manifests as a sudden break of a previously weakened component, such as a rod eye or cylinder weld, even under normal load. In failure analysis, technicians can sometimes distinguish fatigue breaks by “beach mark” patterns on fractured surfaces, indicating a crack that grew gradually, as opposed to a one-time overload that leaves no such pattern.

Warning: Fatigue-related bursting is especially dangerous because it occurs after long-term use, often without obvious external signs. A cylinder might pass a visual check yet still be near failure internally. Heavy equipment buyers in Russia or Kazakhstan, running machines in harsh conditions, should be aware that cold temperatures and constant vibration can accelerate fatigue. For example, in subzero Siberian winters, metal becomes less ductile – meaning cyclic stresses can more easily initiate cracks. Regular inspections and preventive replacements are essential. Look for signs of fatigue such as bending (a slightly bent piston rod is a red flag) or seeping seals that repeatedly fail. If a cylinder experienced any significant overload in the past, its remaining fatigue life may be compromised. When in doubt, consult the cylinder manufacturer for service life guidelines. High-end manufacturers (like Blince) often use advanced alloys and treatments to improve fatigue resistance, but no cylinder lasts forever under constant high stress. Plan to rebuild or retire cylinders after a certain number of cycles or operating hours to avoid an unexpected burst due to metal fatigue.

Oil Contamination and Fluid Quality Issues

Hydraulic oil is the lifeblood of the system – and if that oil becomes contaminated, it can turn into an abrasive slurry that causes cylinder failure. In fact, studies show fluid contamination and oil pollution contribute to about 41% of hydraulic cylinder failures, making it the single biggest culprit. How does dirty oil burst a cylinder? Contamination usually doesn’t explode the barrel outright; instead, it grinds the cylinder from the inside and leads to failures of seals and surfaces. Abrasive particles in the fluid will scratch the inside of the cylinder tube, score the piston rod, clog tiny valve ports, and chew up seals and fittings. As this wear happens, the cylinder’s ability to hold pressure diminishes – seals leak or break apart under load, potentially causing a sudden loss of pressure or uncontrolled movement (which in turn can induce a pressure spike). In extreme cases, contamination can jam a critical valve or relief mechanism, indirectly causing an overpressure scenario that bursts a cylinder.

Common contaminants include dust, dirt, sand, metal shavings, and water. For instance, in a Peruvian mining site or a Chilean construction project with lots of dust, a damaged wiper seal can let grime enter the cylinder fluid. Over time, that grit acts like sandpaper inside the cylinder. Similarly, water entry (from condensation or pressure washing) can cause corrosion and sludge. The oil’s viscosity can change with contamination or improper viscosity selection, leading to erratic cylinder motion and wear. If filters are not changed and oil is not kept clean, contamination damage is inevitable. Once scratches and internal damage reach a critical point, a high-pressure operation can push a weakened seal out or crack a scored cylinder wall.

Warning: Prevention is far easier than repair. Maintain a high standard of hydraulic fluid cleanliness at all times. Industrial buyers should implement strict maintenance schedules: use quality filters, replace them at recommended intervals, and sample the oil for analysis. Watch the rod wipers and seals – faulty wiper seals are a main cause of accelerated contamination ingress, so replace them if worn. In South American climates, also beware of humidity; water in oil reduces lubricity and causes seal swelling, leading to failures. Always use the manufacturer-recommended hydraulic fluid type and viscosity, as the wrong oil (or oil that’s broken down with age) can contribute to internal damage. Clean oil ensures tight-tolerance parts (like the piston and valve spools) move smoothly without grinding – dirty oil is a silent killer of hydraulic cylinders.

Design, Specification, and Installation Flaws

Sometimes the cause of a burst cylinder isn’t how it was used, but how it was designed, chosen, or installed. Using the wrong cylinder for the job – or installing it incorrectly – sets the stage for failure. There are several scenarios where design or installation flaws lead to a cylinder bursting:

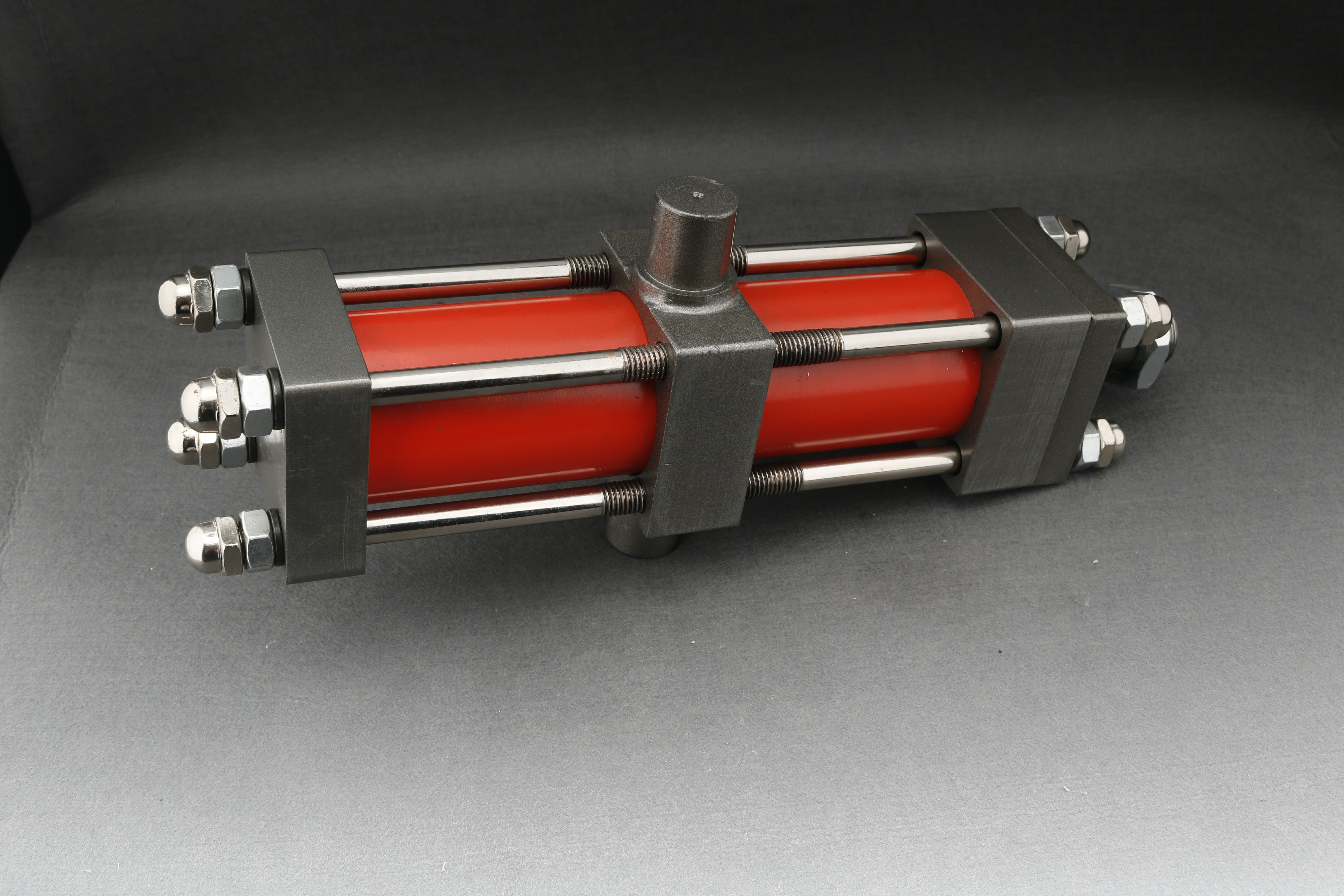

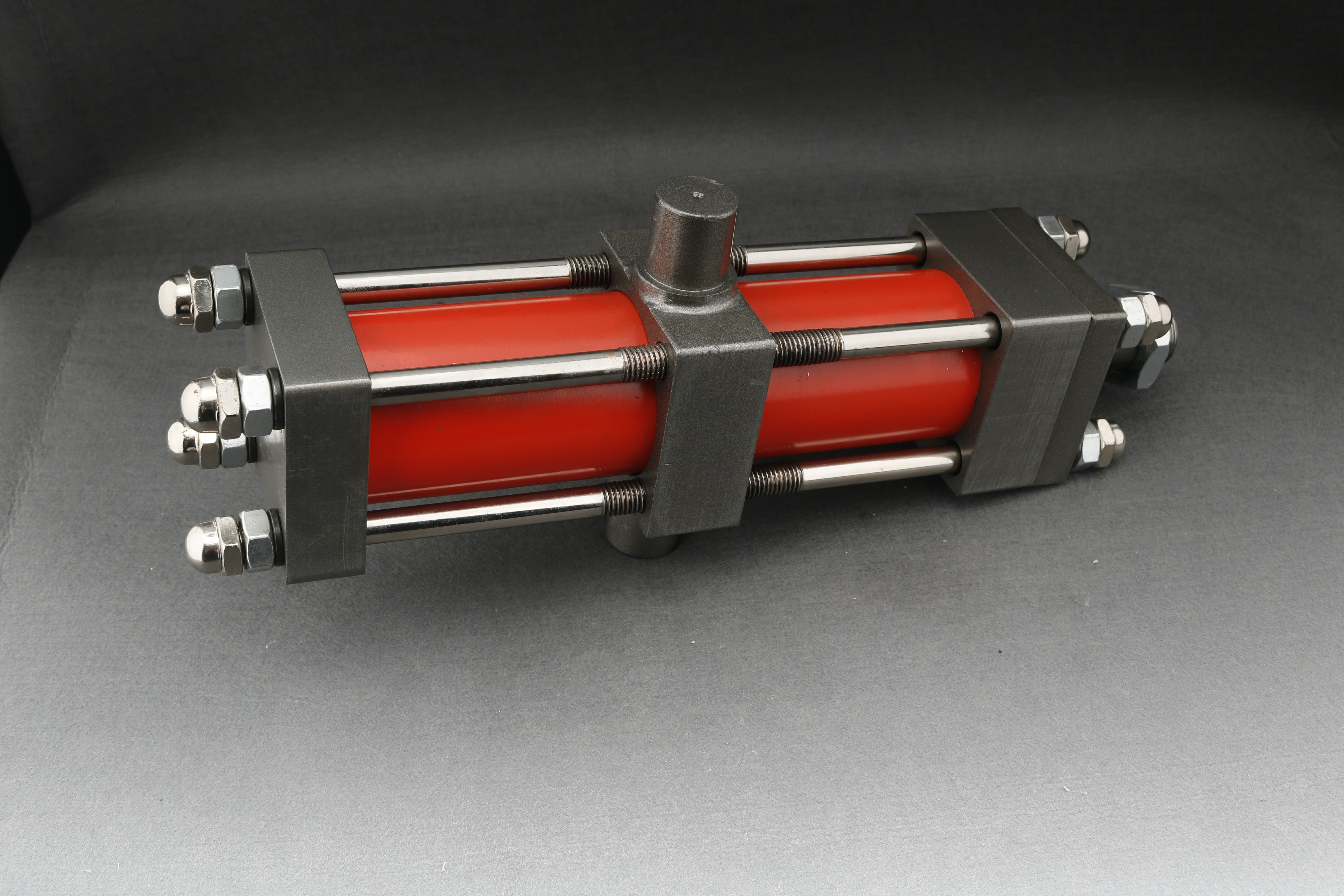

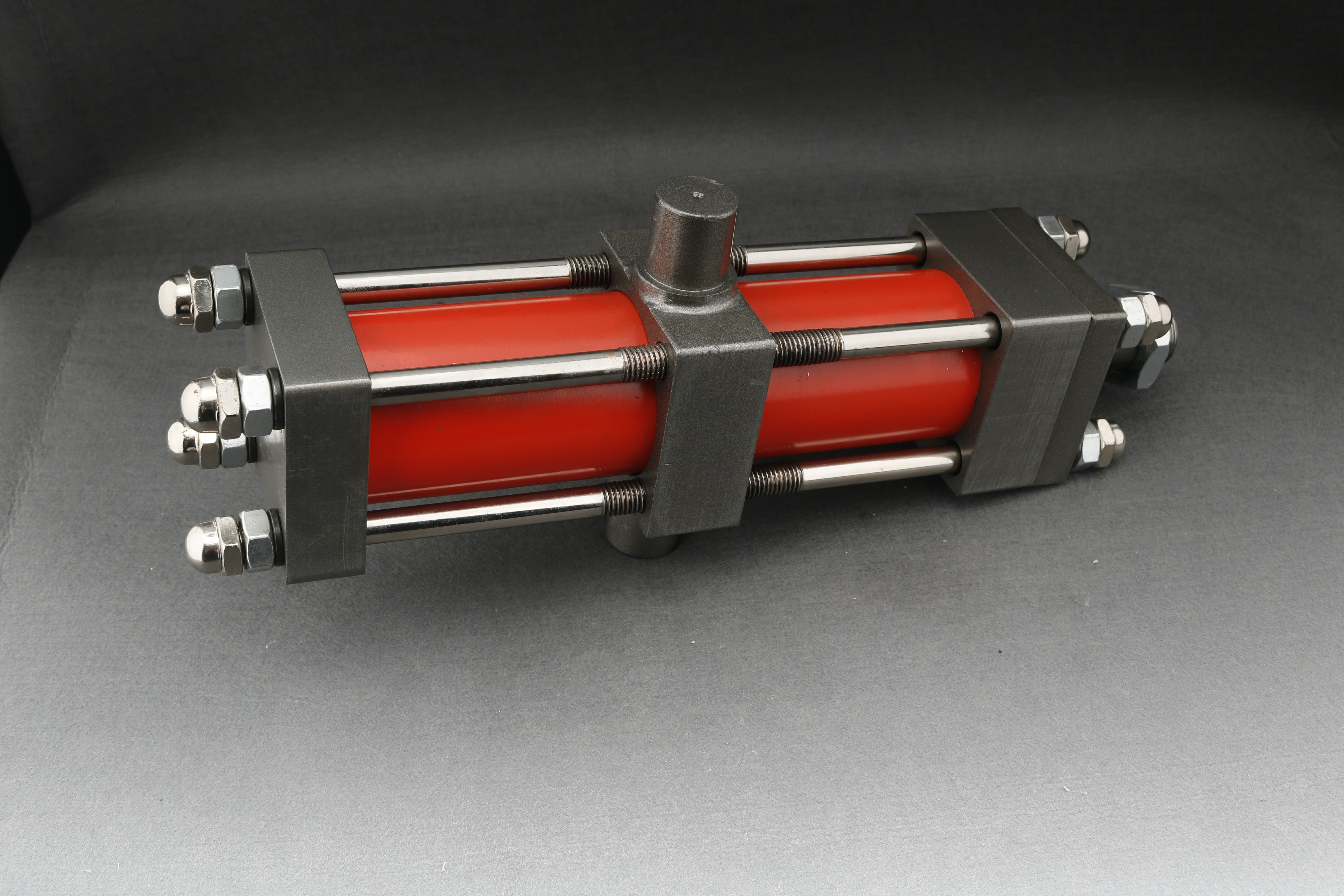

Underspecified or Low-Quality Components: Not all hydraulic cylinders are equal. If a cylinder’s wall thickness or material strength is insufficient for the pressures and loads, the barrel can “balloon” outwards or crack under high pressure. Ballooning (permanent deformation of the tube) is a warning sign that a burst is imminent. This often happens if a cheaper cylinder with thin walls is used where a heavy-duty cylinder is required. Always check the manufacturer’s pressure and load ratings – operating a cylinder beyond its design limits dramatically shortens its life. Likewise, cheap seals or improper seal materials can blow out if they can’t handle the pressure or temperature. In high-temperature environments (e.g. tropical climates or around hot machinery), standard polyurethane seals might soften, and in extreme cold (like high-altitude Andes or Siberian winters), common seals may become brittle. A good design accounts for ambient conditions with appropriate seal materials (e.g. special low-temperature elastomers for cold, Viton for high heat). Using the wrong components is a recipe for failure.

Misalignment and Improper Mounting: Hydraulic cylinders are meant to push and pull in a straight line. If a cylinder is installed at an angle or the machine’s frame shifts under load, the cylinder can experience side loads (bending forces) instead of pure compression/tension. Side loading causes uneven wear on the cylinder – one side of the piston and rod bears extra force, leading to scored cylinder bores and worn seals. Over time, this can oval out the cylinder tube or crack the rod bearing area. Excessive side load can even cause a sudden rod snap or mount breakage, akin to bending a paperclip until it breaks. For example, if a large press cylinder is misaligned by just a few degrees, each stroke drags the piston against the wall; eventually the stress could split the cylinder or snap the mount bolts. Proper installation with precise alignment and flexible mounts (if needed) is critical. Always follow manufacturer guidance on mounting types (e.g. clevis, trunnion, flange) and allowable misalignment. Uneven or shock loading – say a dump truck bed lifting unevenly – can also twist a cylinder. This often manifests as split welds at mounting points or cylinder ends, a catastrophic failure sign that excessive force was applied.

Improper Maintenance or Assembly: A hydraulic cylinder is an assembly of precision parts, and mistakes in assembly or maintenance can cause failures. For instance, loose fasteners (like a gland nut that isn’t torqued properly) can back off and allow internal parts to leak or jam. Outsourced or incorrect spare parts – using a mismatched piston or a rod from another model – might fit poorly and cause stress concentrations (note that using non-OEM or wrong parts has been linked to about 10% of failures). If a cylinder is rebuilt incorrectly (wrong torque, poor bleeding of air, etc.), it might burst under load. Installation also includes ensuring hoses and fittings are correct; a poorly routed hose might prevent a cylinder from moving freely and impose side force, or a half-open valve could create a hydraulic lock.

Warning: To avoid design and installation-related bursts, choose the right cylinder specifications upfront. Industrial buyers in harsh environments should opt for heavy-duty cylinders designed for harsh environments – for example, cylinders with a higher safety factor, corrosion-resistant coating (to prevent rust pitting on rods), and appropriate seal kits for the climate. In coastal Peru or the Chilean mining coast, salty air can corrode rod surfaces; a stainless steel or ceramic-coated rod would be prudent, since corrosion pits on a rod can quickly ruin seals and lead to leaks. In Central Asian winters, ensure the cylinder’s materials (seals, oil, and even metal treatments) are rated for subzero temperatures, to prevent brittle fractures or seal shrinkage. During installation, use skilled technicians who align cylinders correctly and tighten all mounts and connections per spec. Finally, never ignore warning signs during operation: if a cylinder pin keeps coming loose or the cylinder “creeps” under load, it could indicate an installation issue that might lead to a sudden failure. A bit of extra care in design and setup goes a long way to prevent the devastating consequences of a burst cylinder.

FAQ: Hydraulic Cylinder Failure Prevention and Selection

To conclude, here is a brief FAQ addressing common questions about hydraulic cylinder failure and maintenance, with answers geared toward industrial users and buyers in our target regions:

Q: How can I prevent hydraulic cylinder failure in high-pressure systems?

A: Preventing hydraulic cylinder failure starts with proper maintenance and operation. Keep the hydraulic fluid clean – contamination is the #1 cause of cylinder problems, so use quality filters and change oil at recommended intervals. Avoid exceeding the cylinder’s rated pressure or load: use pressure relief valves and never overload your machinery. Regularly inspect cylinders for wear: look at seals for leakage, rods for scratches or bends, and mounts for cracks. Address small issues (like a slight leak or noisy operation) promptly, as these can be early warning signs. Following the manufacturer’s maintenance schedule is crucial – for example, replacing worn seals or bushings before they fail will extend cylinder life. In short, proper use within design limits, routine inspections, and fluid cleanliness are key to preventing failures. High-pressure hydraulic system maintenance should be a scheduled priority, especially for heavy equipment fleets in demanding environments.

Q: How do I identify a damaged or failing hydraulic cylinder?

A: There are several warning signs that a hydraulic cylinder is damaged or starting to fail. Look for visible fluid leaks around the cylinder seals, rod, or ports – oil drips or wet spots indicate seal problems that need attention. Pay attention to performance changes: a cylinder that becomes slow, jerky, or unresponsive may have internal leakage or damage. Unusual noises like banging, knocking, or hissing during operation often signal air in the system or worn components (a healthy cylinder moves smoothly and quietly). Visible damage is a clear red flag – if you notice a bent piston rod, cracked welds at mounting points, or dents in the cylinder barrel, the cylinder is compromised. Also watch for overheating of the hydraulic system or cylinder, as this can suggest internal friction or bypassing fluid. If any of these symptoms appear, the cylinder likely needs repair or replacement before a complete failure (burst) occurs. Early detection of these signs can save you from costly downtime – for example, replacing a leaking seal is much easier than dealing with a snapped cylinder rod later.

Q: What causes a hydraulic cylinder to burst?

A: A hydraulic cylinder typically bursts due to one or more of the extreme conditions discussed above. The most common direct cause is system overpressure – if the pressure inside the cylinder spikes beyond what the cylinder’s construction can handle, it may rupture or split open. Overpressure can result from sudden shock loads, improper relief valve settings, or hydraulic surges in the system. Fatigue failure is another cause: a cylinder that has been weakened by years of cyclic stress or previous overloads might burst even under normal pressure one day (essentially the material cracks after long-term use). Severe contamination or neglect can indirectly cause bursts as well – for instance, if dirty oil jams a valve and creates a pressure lock, or if corrosion has eaten into the cylinder wall. Finally, design and installation flaws (using the wrong cylinder, misalignment, poor-quality parts) can lead to a burst. In summary, anything that overstresses the cylinder’s structure – be it excess pressure, weakened metal, or improper setup – can make a hydraulic cylinder burst. By controlling these factors (pressure, maintenance, alignment, etc.), you greatly reduce the risk of such catastrophic failures.

Q: How do I choose hydraulic cylinders for harsh or extreme environments?

A: Choosing the right hydraulic cylinder for harsh environments is crucial for reliability. First, consider the temperature range: for extreme cold (like high-altitude Andes or Russian winters), select cylinders with seals made for low temperatures (special nitrile or fluorocarbon compounds that remain flexible in the cold) and use appropriate low-temp hydraulic fluid. For high-heat environments, ensure seals and hoses are rated for those temperatures so they don’t degrade. Second, look at corrosion resistance: in humid, coastal, or chemically harsh environments, opt for cylinders with corrosion-resistant coatings (e.g. hard chrome plating, nickel plating, or stainless steel rods) to prevent rust. Protective boots or bellows over the rod can also shield it from dust and salt. Third, consider the duty cycle and load – heavy or continuous duty in harsh conditions calls for heavy-duty cylinder designs (thicker walls, higher safety factors on pressure, and premium wear components). For instance, if you operate in mining or oil fields, a cylinder with an extra margin on pressure rating and larger rod diameter can better handle shock loads. It’s wise to purchase from reputable manufacturers (such as Blince Hydraulic or other established brands) that offer customization for extreme conditions. Discuss your specific environment with the supplier – they may recommend features like upgraded seals, dual wiper seals for extra contamination control, or special rod coatings. By matching the cylinder specifications to the environment – temperature, moisture, dust, load intensity – you ensure maximum lifespan and safety for your hydraulic equipment, even in the harshest conditions.