In our previous article, we discussed the hydraulic pump system and its overall working principle. To briefly review, a hydraulic system is a power transmission technology that uses fluid as the medium to transfer energy. It converts the mechanical energy from an electric motor into fluid energy, which is then delivered to the actuators. The main components of a hydraulic system include the hydraulic pump, actuators (hydraulic motors), valves, and the oil tank.

This article will focus on the hydraulic pump and the hydraulic motor, explaining how they work together within a hydraulic system. Let’s begin with the hydraulic pump.

Classification of Hydraulic Motors

Hydraulic motors are generally divided into two main categories:

Selecting a low-speed hydraulic motor allows the system to output a higher torque at lower speeds.

Within these two categories, hydraulic motors can be further classified based on structure into gear motors, vane motors, and piston motors. Piston motors can also be subdivided into axial piston and radial piston types.

Classification of Hydraulic Pumps

Common types of hydraulic pumps include:

By flow regulation:

Variable-displacement pumps — pumps whose output flow can be adjusted as needed.

Fixed-displacement pumps — pumps with constant output flow.

By structure:

Gear pumps

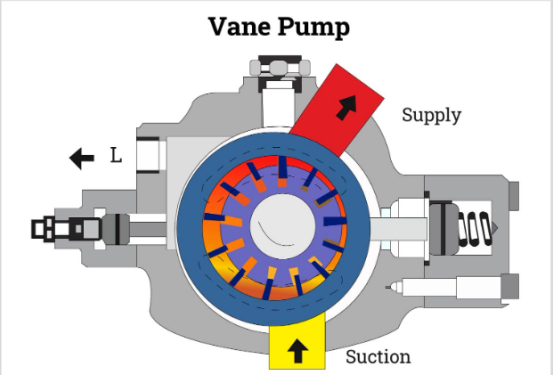

Vane pumps

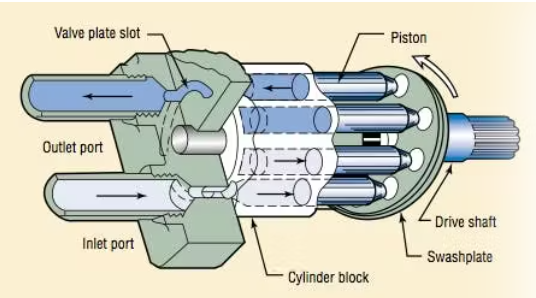

Piston pumps

Gear pumps are compact and simple in structure, have low requirements for oil cleanliness, and are inexpensive. However, they suffer from unbalanced shaft forces, severe wear, and large internal leakage.

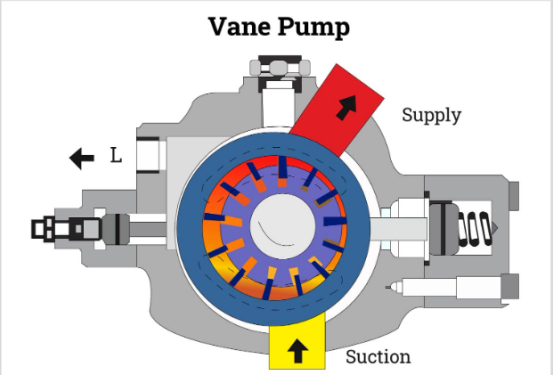

Vane pumps can be single-acting or double-acting. They deliver uniform flow, operate smoothly, produce low noise, and offer higher pressure and volumetric efficiency than gear pumps, though their structure is more complex.

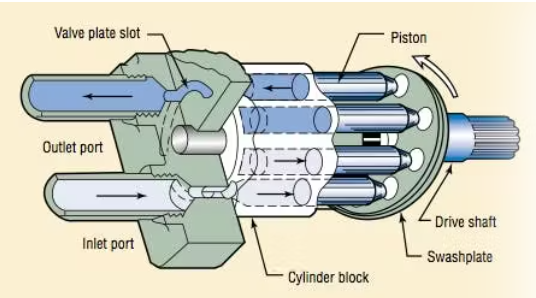

Piston pumps feature high volumetric efficiency, low leakage, and can operate under high pressure, making them suitable for high-power hydraulic systems. However, they are complex in design, require precise materials and manufacturing, are costly, and need highly clean oil.

Components of a Hydraulic Pump

A hydraulic pump typically consists of three main parts: coupling, hydraulic oil tank, and oil filter.

Coupling

The pump shaft cannot withstand radial or axial forces, so pulleys, gears, or sprockets should not be directly mounted on the shaft end. Instead, the drive shaft and pump shaft are connected via a coupling.

If the alignment between the pump and the coupling exceeds tolerance or assembly deviations exist, higher pump speeds will amplify centrifugal force, deforming the coupling, which further increases vibration and noise—eventually shortening pump life. Other issues include loose coupling pins or worn rubber rings that are not replaced in time.

Hydraulic Oil Tank

The oil tank stores hydraulic oil, dissipates heat, separates air, and removes bubbles from the oil.

When selecting an oil tank, capacity should be considered first:

For mobile equipment, the capacity should be 2–3 times the maximum pump flow.

For stationary equipment, 3–4 times.

The oil level must remain above the minimum when all cylinders are extended and below the maximum when retracted.

Structurally, a vertical baffle should be installed along the tank’s longitudinal axis to separate the suction and return zones for better cooling and sedimentation.

Oil Filter

Contaminants smaller than 10 μm usually have little effect, but those larger than 10 μm—especially above 40 μm—significantly reduce pump life.

Solid particles in hydraulic oil increase wear on moving parts; thus, filters are essential to maintain oil cleanliness.

Recommended filtration accuracy:

Axial piston pumps: 10–15 μm

Vane pumps: 25 μm

Gear pumps: 40 μm

High-precision filters are increasingly used today, effectively extending pump lifespan.

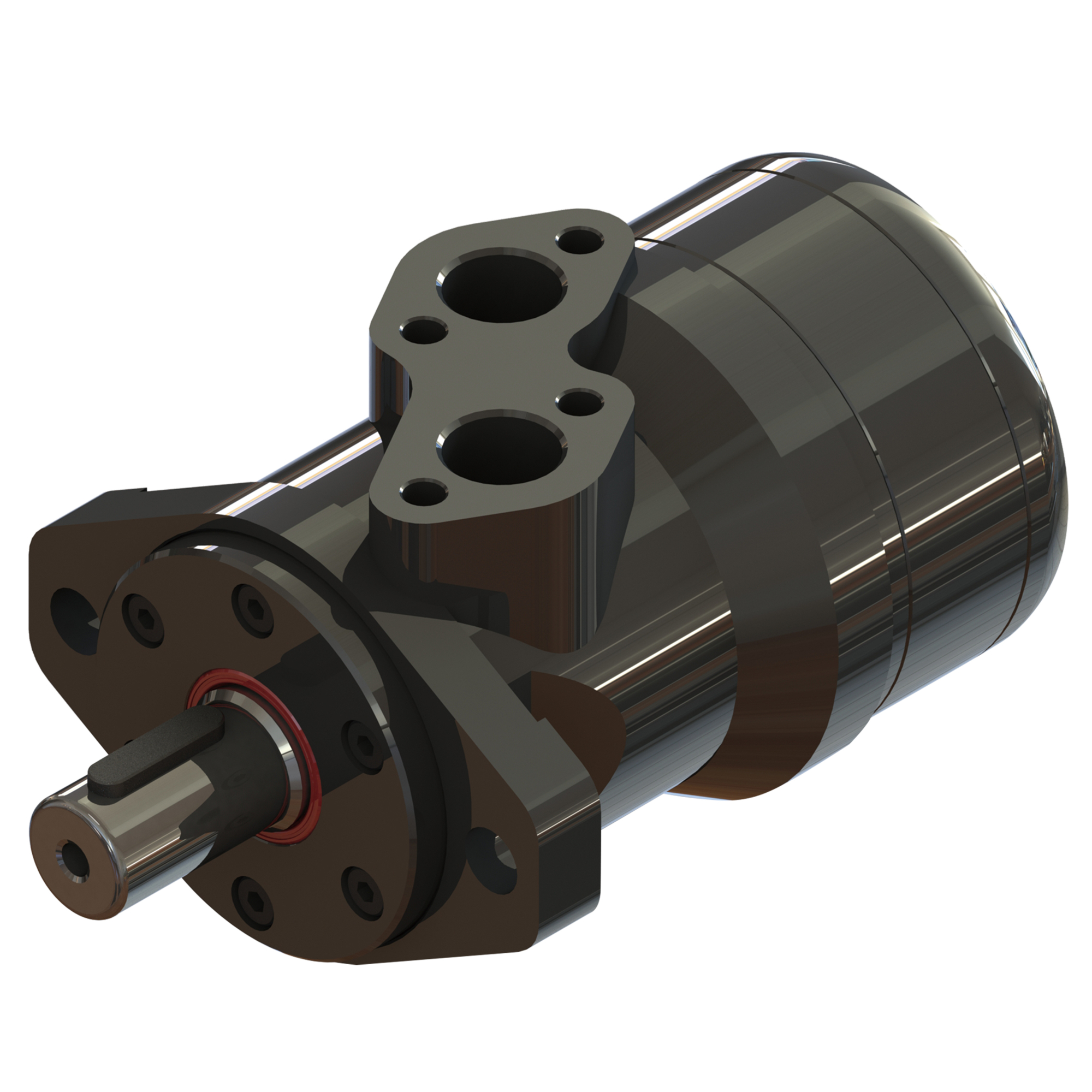

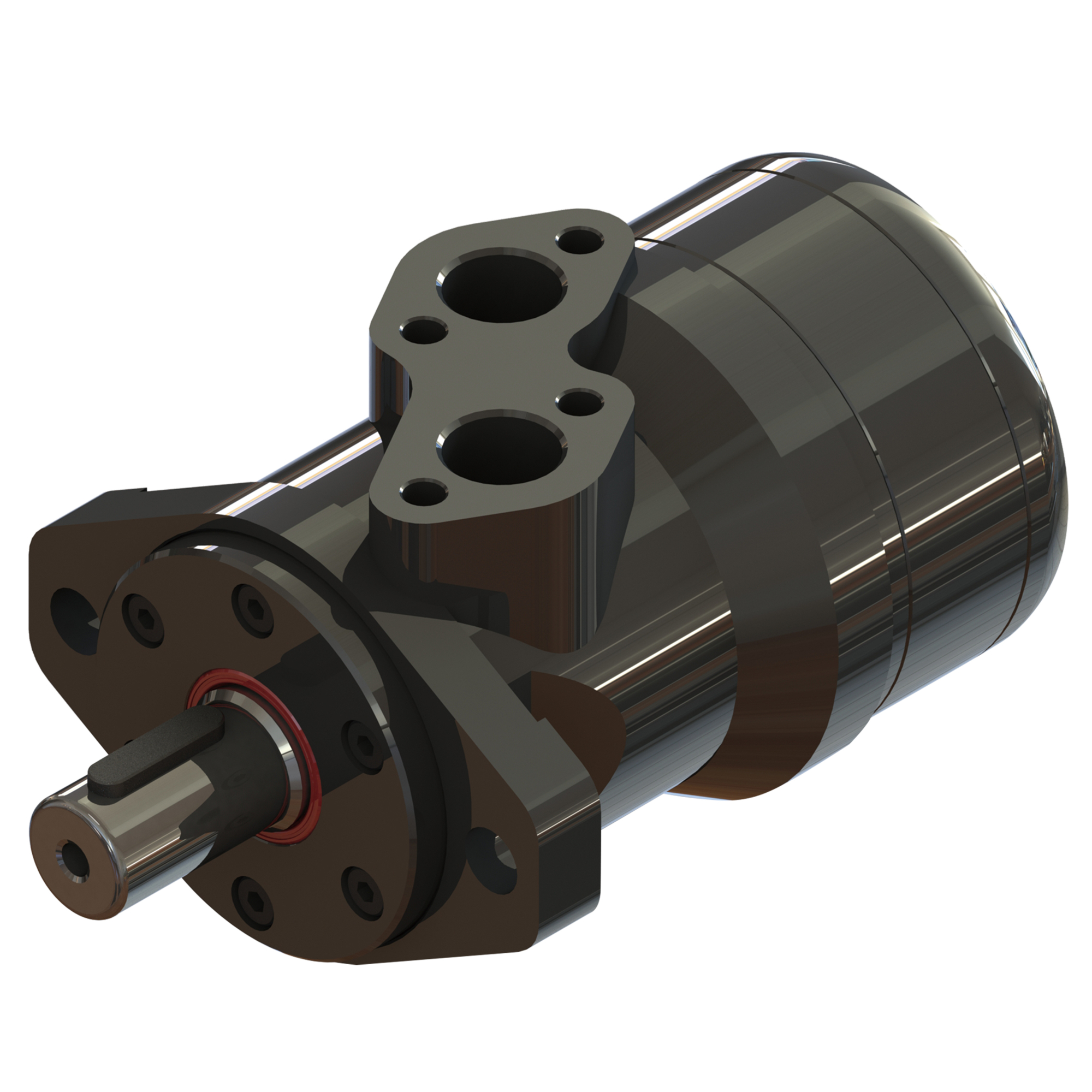

Function of the Hydraulic Motor in hydraulic system

A hydraulic motor converts hydraulic energy into mechanical energy, producing torque and rotational motion. It serves as an essential actuator in hydraulic systems.

Hydraulic motors are generally classified into small torque and large torque types.

With the trend toward higher pressure, greater power, and environmental protection, modern hydraulic motors are designed to operate quietly, smoothly, and with minimal leakage—making large-torque motors increasingly common.

From the energy conversion perspective, hydraulic pumps and motors are reversible hydraulic components. Supplying pressurized fluid to a hydraulic pump can make it act as a motor, and conversely, driving a motor’s shaft with external torque can make it function as a pump.

Both share similar structural elements: variable sealed chambers and corresponding valve mechanisms.

The Role of Hydraulic Pumps in Hydraulic Systems

Simply put, a hydraulic pump is a device that converts mechanical energy into hydraulic energy.

In a hydraulic transmission system, different types of pumps are used to overcome loads and deliver power.

For example, in an excavator’s hydraulic system, the pump provides the pressure needed to lift vehicles or heavy objects.

Most heavy construction machinery uses hydraulic pumps as the system’s core.

Smaller hydraulic pumps also power hydraulic tools—such as cutters, presses, and saws—enabling efficient operation.

Differences Between Hydraulic Pumps and Ordinary Pumps

The main difference lies in their operating principles.

Ordinary pumps maintain a constant liquid flow, while a hydraulic pump’s flow rate depends closely on the system’s load pressure.

Functionally, hydraulic pumps must generate enough pressure to overcome the load, whereas ordinary pumps are designed mainly to circulate or transfer fluids continuously.

How Hydraulic Pumps and Motors Work Together

Once we understand their individual roles, we can examine their coordination:

The hydraulic pump converts mechanical energy from a prime mover (such as an electric motor or diesel engine) into hydraulic energy, transmitted through fluid flow.

The hydraulic motor then receives this energy and reconverts it into mechanical power to drive the load.

Through this conversion cycle, the system provides the mechanical energy necessary to perform work.

Hydraulic systems are widely used in everyday applications—elevators, fuel dispensers, amusement rides, and more—all rely on the seamless cooperation between hydraulic pumps and motors.

Frequently Asked Questions (FAQ)

1. What is the difference between a hydraulic pump and a hydraulic motor?

Answer: A hydraulic pump converts mechanical energy into hydraulic energy (fluid under pressure) while a hydraulic motor converts hydraulic energy back into mechanical energy (torque and rotation).

2. What are the main types of hydraulic motors and how are they classified?

Answer: Hydraulic motors are broadly classified into two major groups:

Low-Speed High-Torque (LSHT) motors

High-Speed Low-Torque (HSLT) motors

Within those, they can be further divided by structure: gear motors, vane motors, and piston motors (which themselves split into axial-piston and radial-piston types).

3. What are the common types of hydraulic pumps and how are they classified?

Answer: Hydraulic pumps are commonly classified by two criteria:

By flow control: variable displacement (flow adjustable) vs. fixed displacement (flow constant)

By structure: gear pumps, vane pumps, and piston pumps.

Gear pumps: compact, simple, less demanding on oil cleanliness, but can have more wear and leakage.

Vane pumps: smoother, quieter, more efficient than gear in many cases, more complex.

Piston pumps: high volumetric efficiency, low leakage, high-pressure capable, used in high-power systems, but more expensive and demanding on oil quality.

4. What components make up a hydraulic pump system?

Answer: A hydraulic pump system typically includes:

A coupling (to connect the drive shaft to the pump shaft)

A hydraulic oil tank (for storage, cooling, air separation, foam elimination)

An oil filter (to remove solid contaminants).

Proper alignment of the coupling, correct oil tank sizing and structure, and appropriate filter precision are all critical for reliable operation.

5. How does a hydraulic motor function in a hydraulic system?

Answer: A hydraulic motor receives pressurized hydraulic fluid and converts that hydraulic energy into mechanical energy: it outputs torque and rotational motion. The motor’s output is influenced by the pressure drop and flow rate through it, hence its output power is largely proportional to its speed when flow and pressure are held constant.

6. How do the hydraulic pump and hydraulic motor work together?

Answer: In a hydraulic system:

The pump converts mechanical energy (from e.g. an electric motor or engine) into hydraulic energy (fluid under pressure and flow).

The hydraulic fluid flows to the motor, which converts that hydraulic energy back into mechanical energy to drive a load.

This coordinated conversion allows the system to deliver mechanical work via fluid power.

7. Why is oil cleanliness and filtration so important in hydraulic systems?

Answer: Solid particles in hydraulic oil (especially those > 10 µm, and notably > 40 µm) can cause accelerated wear of internal moving parts in pumps and motors, reducing efficiency and lifespan. Installing filters with appropriate precision (for example: 10-15 µm for axial-piston pumps, 25 µm for vane pumps, 40 µm for gear pumps) helps maintain system reliability.

8. What should I check if my hydraulic pump is noisy or vibrating?

Answer: Common causes include:

Misalignment between pump and coupling/shaft

Excessive speed or load beyond rating

Air in the suction line or fluid cavitation

Poor oil cleanliness or incorrect oil level/type

Worn or damaged coupling or internal pump parts

Addressing alignment, oil quality, correct installation, and proper speed/load will help reduce noise and extend lifespan.

9. Does the hydraulic pump create pressure in the system?

Answer: Not exactly. The pump’s primary role is to generate flow of fluid; pressure develops in the system when that flow meets resistance (the load, valves, actuators, etc.). Some literature clarifies that attributing pressure generation directly to the pump alone is a misconception.

10. What efficiency measures apply to hydraulic pumps and motors?

Answer: There are three key efficiency categories:

Volumetric efficiency: actual flow ÷ theoretical flow

Mechanical/hydraulic efficiency: theoretical torque ÷ actual torque (or related mechanical losses)

Overall efficiency: the product of volumetric efficiency and mechanical/hydraulic efficiency.

Blince Team

Blince Hydraulic is an industry-leading company specializing in complete hydraulic solutions. With over 20 years of experience and long-term cooperation with more than 5,000 global customers, we focus on high-performance hydraulic motors, hydraulic pumps, steering control units, directional valves, hydraulic cylinders, hoses, fittings, and other one-stop hydraulic system solutions.

Our factory group is equipped with advanced CNC machining centers, automated production lines, and precision testing equipment. Certified with ISO9001, CE, SGS, and UL, Blince provides fast, efficient, and high-quality hydraulic solutions to customers in more than 100 countries worldwide. Whether you need small batch customization or large-scale production, we can meet your demands with reliable delivery and competitive performance.

Choose Blince technology — it means efficiency, durability, and professionalism in every hydraulic product we deliver.

To learn more, visit our website: www.blince.com

Tel: +86 180 3845 8522

Email: sales01@blince.com

Website: https://www.blince.com